Right Now

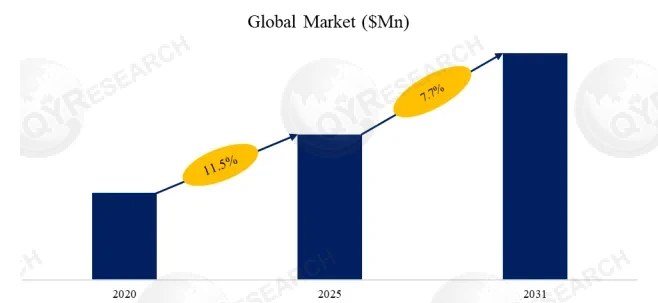

Hybrid Servo Motor Cable market :CAGR of 7.70% during the forecast period 2026-2031

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report “Hybrid Servo Motor Cable- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”. Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The global market for Hybrid Servo Motor Cable was estimated to be worth US$ 101 million in 2024 and is forecast to a readjusted size of US$ 170 million by 2031 with a CAGR of 7.7% during the forecast period 2025-2031.

【Get a free sample PDF of this report (Including Full TOC, List of Tables & Figures, Chart)】

https://www.qyresearch.com/reports/4776264/hybrid-servo-motor-cable

Hybrid Servo Motor Cable Market Summary

A hybrid servo motor cable combines power supply and data transmission within a single cable, optimizing connectivity for servo motor systems. It streamlines installation, reduces cable clutter, and enhances performance in industrial automation.

The global Hybrid Servo Motor Cable market was valued at US$ 100.95 million in 2024 and is anticipated to reach US$ 170.15 million by 2031, witnessing a CAGR of 7.70% during the forecast period 2026-2031.

North American market for Hybrid Servo Motor Cable is estimated to increase from $ 25.99 million in 2024 to reach $ 44.64 million by 2031, at a CAGR of 7.98% during the forecast period of 2024 through 2031.

Asia-Pacific market for Hybrid Servo Motor Cable is estimated to increase from $ 32.28 million in 2024 to reach $ 59.07 million by 2031, at a CAGR of 8.99% during the forecast period of 2024 through 2031.

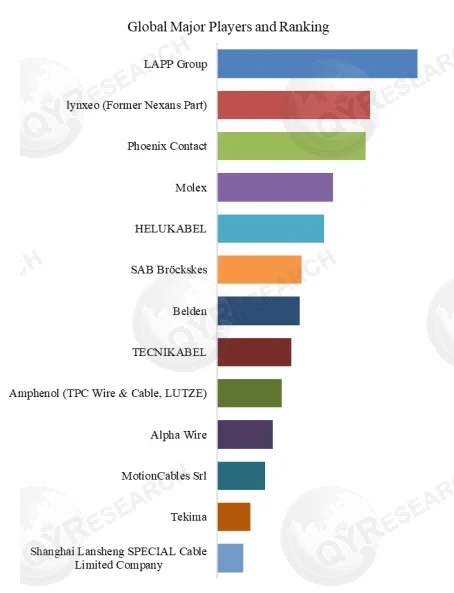

The major global manufacturers of Hybrid Servo Motor Cable include Igus, LAPP Group, lynxeo (Former Nexans Part), Phoenix Contact, Molex, HELUKABEL, SAB Bröckskes, Belden, TECNIKABEL, Amphenol (TPC Wire & Cable, LUTZE), Alpha Wire, MotionCables Srl, Tekima, Shanghai Lansheng SPECIAL Cable, etc. In 2024, the world's top three vendors accounted for approximately 35.52% of the revenue.

Figure00001. Global Hybrid Servo Motor Cable Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Hybrid Servo Motor Cable Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure00002. Global Hybrid Servo Motor Cable Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Hybrid Servo Motor Cable Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

This report profiles key players of Hybrid Servo Motor Cable such as Igus, LAPP Group, Lynxeo (Former Nexans Part), Phoenix Contact, Molex.

In 2023, the global top five Hybrid Servo Motor Cable players account for 52% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Hybrid Servo Motor Cable.

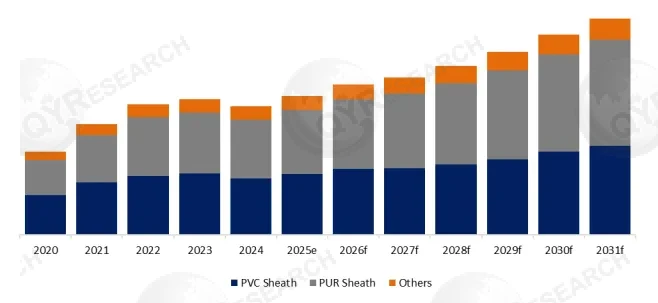

Figure00003. Hybrid Servo Motor Cable, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Hybrid Servo Motor Cable Market Report 2024-2030.

In terms of product type, PUR Sheath is the largest segment, hold a share of 46.1%,

In terms of product application, Industrial Automation is the largest application, hold a share of 66.1%,

Key Trends

Advancement Toward High Flexibility and Bend Resistance

With the increasing use of robotics, automated machinery, and drag chain systems, there is a growing demand for cables that can withstand continuous bending and dynamic motion. Hybrid servo motor cables are evolving to use ultra-fine stranded copper conductors and high-flex jacket materials such as PUR and TPE. These designs allow for tight bending radii and long service life, especially in high-movement environments like robotic arms, CNC machines, and linear motion systems. Flex life measured in millions of cycles is becoming a key performance benchmark.

Rising Importance of EMC and Signal Integrity

In industrial environments where servo systems operate alongside inverters, PLCs, and fieldbus networks, electromagnetic interference (EMI) poses serious challenges to stable performance. As a result, modern hybrid cables are adopting multi-layer shielding (e.g., aluminum foil and braided copper) and segmented shielding designs that isolate power and signal wires. These improvements significantly enhance signal integrity for encoder feedback and reduce crosstalk, helping meet global EMC standards and certifications such as CE and UL.

Trend Toward Modular and Integrated Wiring

Traditional servo wiring requires separate cables for power, feedback, and brake signals, increasing installation time and complexity. Hybrid servo motor cables integrate power, encoder, signal, and brake wires into a single cable, enabling streamlined wiring, reduced space usage, and easier maintenance. This trend supports the modular design needs of OEMs and manufacturers building compact and space-efficient machines, while also reducing total cost of ownership.

Increased Focus on Environmental Compliance and Global Standards

As industries adopt greener practices, hybrid servo motor cables are shifting toward halogen-free, low-smoke (LSZH), and recyclable materials to minimize toxic emissions during fires and improve workplace safety. At the same time, customers increasingly require compliance with international safety and environmental certifications such as UL, CE, CSA, RoHS, and REACH. Manufacturers that meet these standards are better positioned to compete in export-heavy markets like Europe, North America, and Japan.

Current State of Hybrid Servo Motor Cables

Integrated Wiring Has Become an Industry Norm

Hybrid servo motor cables have gained widespread adoption in industrial automation, as they combine power, signal, and feedback lines into one cable. This integration simplifies wiring layouts, reduces installation time, and improves space efficiency in control cabinets and machines.

Widely Used in Dynamic Industrial Applications

These cables are now commonly used in robotics, CNC machines, drag chains, and automated production lines, especially in sectors such as automotive, packaging, semiconductor manufacturing, and material handling. Their flexibility and high EMI shielding performance make them essential in high-speed, high-precision motion control.

Material Innovation and Safety Standards

Most hybrid servo cables use advanced materials such as Tinned Copper conductors, XLPE insulation, and PUR jackets to ensure heat resistance, flexibility, and durability. The cables are also increasingly designed to meet international safety and environmental standards such as UL, CE, RoHS, and REACH.

Future Development of Hybrid Servo Motor Cables

Move Toward Smarter Cables (Smart Cable Integration)

In the future, hybrid cables may incorporate built-in sensors for temperature, stress, or data diagnostics, enabling predictive maintenance and reducing unplanned downtime. These “smart cables” will be key in Industry 4.0 environments.

Standardization and Modularization Across Brands

Currently, many cables are designed for specific motor/drive systems. Going forward, there is a growing need for cross-brand standardization, including universal connectors, pin layouts, and cable structures, allowing for easier integration and reduced procurement complexity.

Hybrid Servo Motor Cables are already essential in modern automation for their ability to integrate multiple functions into a single durable, flexible cable. Today, they serve as a reliable backbone in dynamic industrial systems. Looking forward, they are poised to become smarter, more standardized, and environmentally responsible, aligning with global trends in digitalization, interoperability, and sustainability.

Hybrid Servo Motor Cables are at the center of modern industrial automation, evolving in both technological sophistication and market relevance. Technically, current hybrid cables have advanced significantly from their early forms. Manufacturers now implement multi-layer electromagnetic shielding, such as combinations of aluminum foil, copper braids, and drain wires, to meet the increasing need for high-frequency signal integrity in servo feedback systems like EnDat, BiSS, and Hiperface. This ensures accurate position control even in electrically noisy industrial environments. At the same time, the internal structure of these cables has become more refined—torsion-resistant geometries, concentric twisting, and high strand-count fine wires enable exceptional flexibility and long life in dynamic applications, particularly where continuous bending, torsion, and tight radii are present, such as in robotic joints and 6-axis arms.

In parallel, there is a notable shift toward brand-specific compatibility, with cable producers offering hybrid variants that align with the electrical and mechanical specifications of servo systems from major players like Siemens, Yaskawa, Beckhoff, and Fanuc. This has improved ease of integration and reduced errors in connection during machine assembly and maintenance.

Looking ahead, the development of hybrid servo motor cables is being fuelled by several promising opportunities. First, the proliferation of collaborative robots and lightweight automation systems in industries like electronics, healthcare, and logistics is creating demand for smaller-diameter, ultra-flexible hybrid cables that can fit in compact spaces without compromising performance. Second, as more factories adopt decentralized drive architectures, where servo drives are distributed across the machine instead of concentrated in a control cabinet, there is growing need for hybrid cables capable of long-distance transmission while maintaining low power loss and stable signal performance. This trend supports modular machine designs and flexible factory layouts.

Finally, global industrial transformation is expanding the market. Developing economies are rapidly investing in automated manufacturing, requiring hybrid servo cables that balance performance and affordability. Simultaneously, factories in developed regions are retrofitting older systems to align with Industry 4.0 standards, often replacing legacy multi-cable setups with high-efficiency hybrid alternatives to streamline wiring, reduce maintenance, and prepare for smart system integration.

The report provides a detailed analysis of the market size, growth potential, and key trends for each segment. Through detailed analysis, industry players can identify profit opportunities, develop strategies for specific customer segments, and allocate resources effectively.

The Hybrid Servo Motor Cable market is segmented as below:

By Company

Igus

LAPP Group

Lynxeo (Former Nexans Part)

Phoenix Contact

Molex

HELUKABEL

SAB Bröckskes

Belden

TECNIKABEL

Amphenol (TPC Wire & Cable, LUTZE)

Alpha Wire

MotionCables Srl

Tekima

Shanghai Lansheng SPECIAL Cable Limited Company

Segment by Type

PVC Sheath

PUR Sheath

Others

Segment by Application

Industrial Automation

Logistics

Others

Each chapter of the report provides detailed information for readers to further understand the Hybrid Servo Motor Cable market:

Chapter 1: Introduces the report scope of the Hybrid Servo Motor Cable report, global total market size (valve, volume and price). This chapter also provides the market dynamics, latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry. (2020-2031)

Chapter 2: Detailed analysis of Hybrid Servo Motor Cable manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc. (2020-2025)

Chapter 3: Provides the analysis of various Hybrid Servo Motor Cable market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments. (2020-2031)

Chapter 4: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.(2020-2031)

Chapter 5: Sales, revenue of Hybrid Servo Motor Cable in regional level. It provides a quantitative analysis of the market size and development potential of each region and introduces the market development, future development prospects, market space, and market size of each country in the world..(2020-2031)

Chapter 6: Sales, revenue of Hybrid Servo Motor Cable in country level. It provides sigmate data by Type, and by Application for each country/region.(2020-2031)

Chapter 7: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc. (2020-2025)

Chapter 8: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 9: Conclusion.

Benefits of purchasing QYResearch report:

Competitive Analysis: QYResearch provides in-depth Hybrid Servo Motor Cable competitive analysis, including information on key company profiles, new entrants, acquisitions, mergers, large market shear, opportunities, and challenges. These analyses provide clients with a comprehensive understanding of market conditions and competitive dynamics, enabling them to develop effective market strategies and maintain their competitive edge.

Industry Analysis: QYResearch provides Hybrid Servo Motor Cable comprehensive industry data and trend analysis, including raw material analysis, market application analysis, product type analysis, market demand analysis, market supply analysis, downstream market analysis, and supply chain analysis.

and trend analysis. These analyses help clients understand the direction of industry development and make informed business decisions.

Market Size: QYResearch provides Hybrid Servo Motor Cable market size analysis, including capacity, production, sales, production value, price, cost, and profit analysis. This data helps clients understand market size and development potential, and is an important reference for business development.

Other relevant reports of QYResearch:

Global Hybrid Servo Motor Cable Market Outlook, In‑Depth Analysis & Forecast to 2031

Global Hybrid Servo Motor Cable Market Research Report 2025

Global Hybrid Servo Motor Cable Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Global Hybrid Servo Motor Cable Market Insights, Forecast to 2031

About Us:

QYResearch founded in California, USA in 2007, which is a leading global market research and consulting company. Our primary business include market research reports, custom reports, commissioned research, IPO consultancy, business plans, etc. With over 18 years of experience and a dedicated research team, we are well placed to provide useful information and data for your business, and we have established offices in 7 countries (include United States, Germany, Switzerland, Japan, Korea, China and India) and business partners in over 30 countries. We have provided industrial information services to more than 60,000 companies in over the world.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.