Right Now

Prismatic Cell Terminal Post Research:CAGR of 20.7% during the forecast period

Prismatic Cell Terminal Post Market Summary

The prismatic cell terminal post refers to a pair of conductive metal parts inside the battery, which are connected to the positive and negative plates of the battery respectively, and extend outward through special holes on the shell, as a bridge between the battery and the external circuit and undertake the important task of transmitting electric energy. These poles are usually made of materials with excellent electrical conductivity, such as copper or aluminum alloy, with high electrical conductivity, good mechanical strength and corrosion resistance to ensure stable and efficient current transmission during battery charge and discharge, while also considering safety and preventing potential safety hazards caused by short circuit or leakage; The structural design of the pole comprises a contact end, an extension section and a connection end, wherein the contact end is closely connected with the positive and negative electrode plates inside the battery, the extension section is responsible for passing through the shell from the inside of the battery to the outside, and the connection end provides a convenient way for the pole to be smoothly connected with an external circuit or charging equipment, and the size and quality of the pole are determined according to the design and application requirements of the battery, and have a direct impact on the overall performance and reliability of the battery.

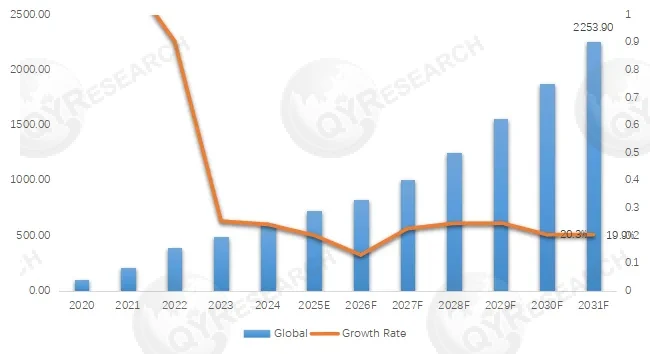

According to the new market research report "Global Prismatic Cell Terminal Post Market Report 2025-2031", published by QYResearch, the global PrismaticCell Terminal Post market size is projected to grow from USD 607.43 million in 2024 to USD 2253.9 million by 2031, at a CAGR of 20.7% during the forecast period.

Figure00001. Global Prismatic Cell Terminal Post Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch: Global PrismaticCell Terminal Post Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

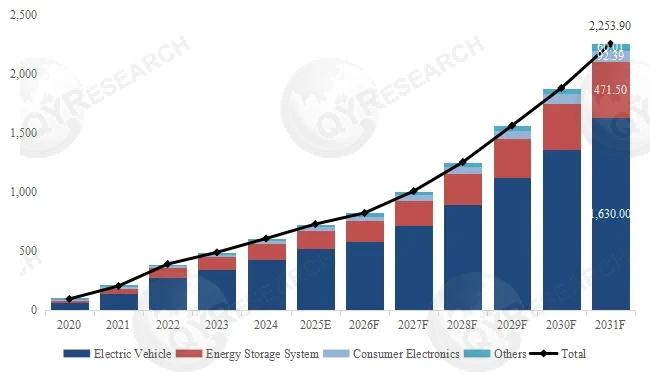

Figure00002. Global Prismatic Cell Terminal Post Market Share by Application Area (US$ Million) (Ranking is based on the revenue of 2025, continually updated)

Above data is based on report from QYResearch: Global PrismaticCell Terminal Post Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

According to the figure, electric vehicle have the largest market share.

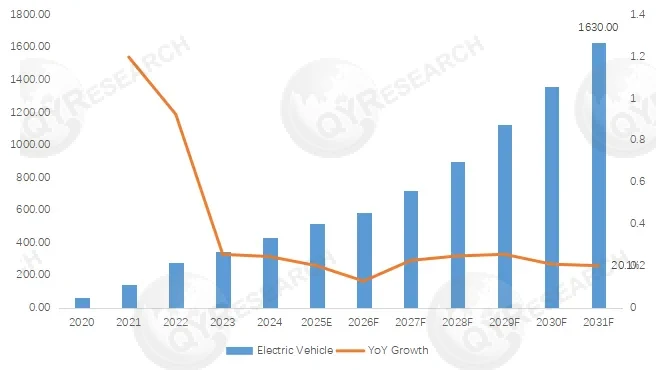

Figure00003. Prismatic Cell Terminal Post, Market Share of Electric Vehicle(US$ Million)

Based on or includes research from QYResearch: Global PrismaticCell Terminal Post Market Report 2025-2031.

The prismatic cell terminal post refers to the core conductive component that adopts aluminum alloy shell packaging and undertakes the current transmission task between the internal battery cell and the external circuit of the battery. Its design ensures high conductivity, mechanical strength and thermal stability by optimizing the structure and materials to support the high-rate charge and discharge requirements of electric vehicles, and relies on laser welding, injection molding sealing and other processes to ensure safety, explosion prevention and long-term reliability.

The future development trend in the field of electric vehicles focuses on: material and structure innovation, such as copper-aluminum composite pole or carbon fiber reinforced material to further reduce resistance and weight, adapt to high-voltage fast-charging platform; Manufacturing process upgrade, improve connection accuracy through polymer diffusion welding and fully automated assembly, and reduce thermal deformation risk; Function integration, embedded temperature/voltage sensor to realize pole intelligence, real-time collaborative battery management system to optimize thermal runaway warning; Safety enhancement, development of impact-resistant honeycomb structure and self-power-off design to cope with collision scenarios, and promotion of solid-state battery adaptation pole development. In addition, lightweight and recycling technologies will become a critical path to reduce carbon emissions and promote the environmental protection of pole assemblies throughout their life cycle.

The prismatic cell terminal post refers to the key conductive component used for mobile phones, tablet computers, smart wearable devices and other products in the field of consumer electronics. Its main body is made of aluminum alloy, which realizes current conduction between the internal cells of the battery and the external circuit through precise structure, while ensuring lightweight, high-energy density and safe sealing.

Future development trends focus on material and structural innovation: the use of copper-aluminum composite poles or nano-coatings to optimize conductivity and reduce contact resistance, adapt to fast charge requirements; lightweight design to further reduce volume, support consumer electronics ultra-thin trend. High integration and intelligence: combine laser welding, polymer diffusion welding and other processes to improve the integration degree of the pole and battery cover plate, reduce the risk of thermal deformation; and explore integrated temperature/voltage sensing modules to achieve real-time monitoring of battery status. Sustainability upgrade: Develop environmentally friendly aluminum alloy materials and recyclable structures to respond to the low carbon requirements of consumer electronics, while reducing costs and improving efficiency through automated production.

Future consumer electronics will rely on such high-performance poles to drive devices towards longer life, smaller size and higher security.

In terms of product application, application one is the largest application, hold a share of xx%,

The prismatic cell terminal post refers to the key conductive component connecting the internal battery cell and external circuit in the energy storage system. It is usually made of aluminum alloy or copper-aluminum composite material, which undertakes the core functions of high current transmission, system sealing and safety protection. Its design needs to meet the requirements of high conductivity, corrosion resistance, mechanical strength and long-term stability to support the high-rate charge and discharge of the energy storage system, stabilize the fluctuation of renewable energy and ensure the stability of the power grid.

The future development trend in the field of energy storage focuses on: material and structure innovation, such as copper aluminum composite pole to further optimize conductivity and reduce the amount of precious metals, while developing high fatigue resistance composite materials to extend service life; lightweight and high energy density design, through the pole structure optimization to reduce internal space occupation, improve battery volume utilization; Intelligence and safety enhancement, embedded temperature/voltage sensors for real-time status monitoring, combined with PTC thermistors or short-circuit protection structures to prevent thermal runaway; process upgrading and standardization, using laser welding 3.0 technology to improve sealing accuracy and production efficiency, and promoting standardization of pole size and interface to adapt to modular energy storage systems; green manufacturing, development of recyclable materials and low energy consumption processes to respond to low carbon requirements. With the evolution of energy storage systems towards large-scale, high-safety and long-life, pole technology will continue to promote the reliability and economy of energy storage batteries.

With its high conductivity, corrosion resistance and structural stability, the prismatic cell terminal post is widely used in consumer electronics, electric vehicles and energy storage systems, but also in industrial power equipment.(such as electric forklifts, AGV logistics vehicles, port machinery and mining vehicles), special equipment (aerospace auxiliary power supply, military equipment, marine engineering), infrastructure (rail transit backup power supply, communication base station, smart grid), medical equipment (mobile DR, ECMO), ship electrification (yacht, port operation ship) and other scenarios play a key role to meet high-intensity, extreme environment and customization requirements.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.