Right Now

Capsule Appearance Inspection Machines Market Research:the market size is projected to grow from USD 265.16 million in 2025 to USD 360.67 million by 2031

The capsule appearance inspection machine is a device specially designed for automatic inspection of the surface and internal quality of capsule preparations. It uses high-resolution cameras, sensor technology and advanced image processing algorithms to quickly and accurately identify defects such as color deviation, cracks, bubbles, foreign matter contamination, and size inconsistency in capsules. The device is designed to ensure that each capsule meets strict pharmaceutical standards, improve product quality, and reduce errors caused by manual inspection. It is widely used in production lines in the pharmaceutical industry to achieve efficient and accurate quality control.

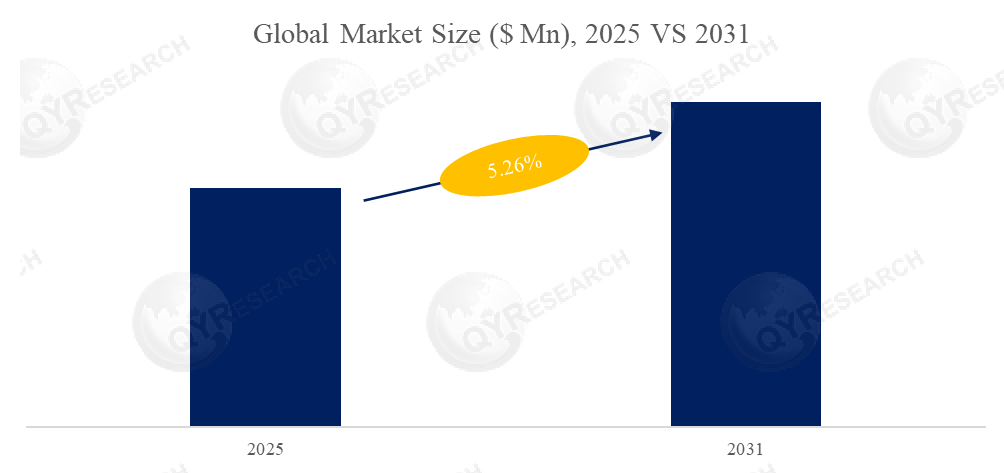

According to the new market research report "Capsule Appearance Inspection Machines - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031", published by QYResearch, the global Capsule Appearance Inspection Machines market size is projected to grow from USD 265.16 million in 2025 to USD 360.67 million by 2031, at a CAGR of 5.26% during the forecast period.

Figure00001. Global Capsule Appearance Inspection Machines Market Size (US$ Million), 2025-2031

Source: QYResearch, "Capsule Appearance Inspection Machines - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

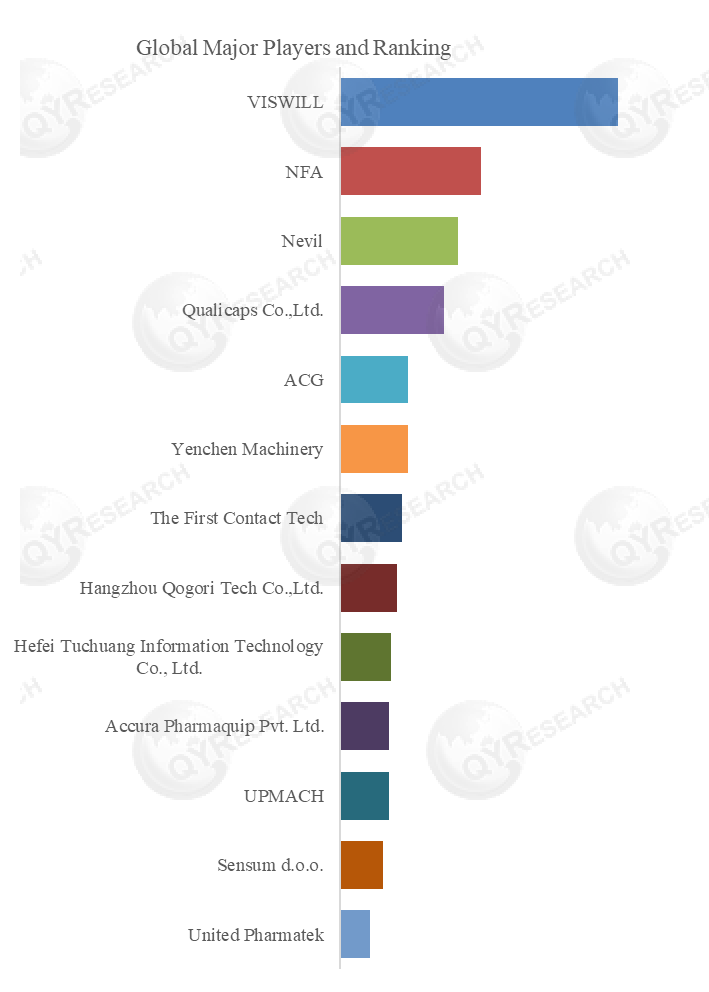

Figure00002. Global Capsule Appearance Inspection Machines Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Capsule Appearance Inspection Machines - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

This report profiles key players of Capsule Appearance Inspection Machines such as VISWILL,NFA,Nevil,Qualicaps Co.,Ltd

In 2024, the global top five Capsule Appearance Inspection Machines players account for 45.03% of market share in terms of revenue. Above figure shows the key players ranked by revenue in Capsule Appearance Inspection Machines.

Market Drivers:

1. As consumers' quality requirements for medicines and health products increase, capsule appearance inspection machines can effectively detect defects such as cracks, deformations, inconsistent colors, etc., ensuring that products meet high standards of quality specifications.

2. The strict regulations of drug regulatory agencies in various countries (such as FDA, EMA) on the pharmaceutical industry have promoted companies to adopt automated testing equipment. Capsule appearance inspection machines can help companies meet the requirements of GMP (Good Manufacturing Practice) and other relevant standards.

3. Automated appearance inspection machines can significantly reduce the time and cost of manual inspections, while providing higher inspection speed and accuracy, which helps to meet the needs of large-scale production.

4. Manual inspections are prone to fatigue and misjudgment, while automated appearance inspection machines can maintain consistency and accuracy, reducing product defects caused by human factors.

5. Modern capsule appearance inspection machines are usually equipped with data recording functions, which can record the inspection results of each product in detail, facilitating subsequent quality tracking and problem location, which is crucial for recall management and responsibility division.

Restraint:

1. Purchasing and installing advanced capsule appearance inspection machines requires a high initial investment, including equipment procurement, installation and commissioning, and personnel training costs, which may be a large burden for some small and medium-sized enterprises.

2. These systems often involve complex image processing technology and precision mechanical design, requiring professional technicians to operate and maintain, increasing the operating costs and technical thresholds of enterprises.

3. Different types of capsules (such as size, shape, color differences) and capsule characteristics produced under different production processes may challenge the applicability of appearance inspection machines, requiring customized solutions or adjustments to existing equipment settings, which increases the difficulty of implementation.

4. In order to maintain optimal performance and respond to new market demands, the software part of the capsule appearance inspection machine needs to be regularly updated and maintained, which also means continuous cost investment.

5. Although capsule appearance inspection machines have obvious advantages, in some regions or industries, traditional manual inspection methods still dominate, and the market's acceptance of new technologies needs to be further improved.

About The Authors

Yaping Zhao - Lead Author

Email: zhaoyaping@qyresearch.com

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.