Right Now

Optical Fiber in Stainless Steel Tube Research Report: the global Optical Fiber in Stainless Steel Tube market size is expected to reach US$995.3 million in 2030

Optical Fiber in Stainless Steel Tube is a structure where the optical fiber is placed inside a stainless steel metal tube, which is used to protect the fiber from external physical and environmental influences while ensuring the safety and reliability of signal transmission. This structure typically has good mechanical strength, corrosion resistance, and high-temperature resistance, and is widely used in electricity, communication, submarine cables, and other applications.

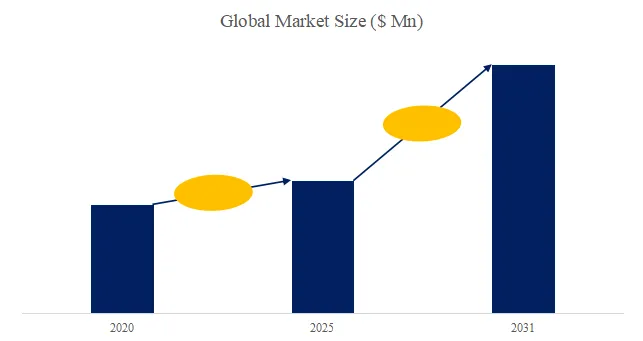

According to the latest research report from QYResearch, the global Optical Fiber in Stainless Steel Tube market size is expected to reach US$995.3 million in 2030, with a compound annual growth rate (CAGR) of 5.61% in the next few years.

Figure00001. Global Optical Fiber in Stainless Steel Tube Market Size (US$ 995.3 Million), 2019-2030

Source: QYResearch, "Optical Fiber in Stainless Steel Tube - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

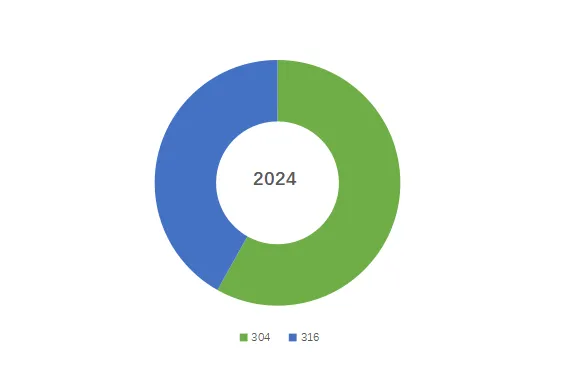

Figure00002. Optical Fiber in Stainless Steel Tube,Global Market Size, Segmented by Product Type, 304 Type Dominates

Source: QYResearch, "Optical Fiber in Stainless Steel Tube - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

In terms of product types, 304 type is currently the most important product segment, accounting for about 58.13% of the market share.

Main Drivers:

1. Promotion of Fiber Optic Sensing Applications by Industry 4.0:Industry 4.0 aims to achieve the intelligentization and automation of factories, in which fiber optic sensing technology plays a crucial role. In harsh industrial environments such as high - temperature, high pressure, and corrosive conditions, ordinary optical fibers are prone to damage, which affects their normal functions. Stainless steel metal tubes provide effective physical protection for optical fibers, enhancing their durability. For example, in chemical production workshops, there are a large number of corrosive gases and liquids. Stainless steel metal tubes can prevent these chemical substances from corroding the optical fibers, ensuring the long term stable operation of the fiber optic sensing system and enabling real time monitoring of key parameters such as temperature, pressure, and flow during the production process.

2. Demand from the Oil, Gas, and Chemical Industries:The production environments in the oil, gas, and chemical industries are extremely harsh, often facing challenges such as high temperature, high pressure, and strong corrosion. During the production, transportation, and storage processes in these industries, optical fibers are required for various parameter monitoring and data transmission. Stainless steel metal tubes have good mechanical properties and corrosion resistance, providing reliable protection for optical fibers. For instance, on an oil drilling platform, the high temperature and high pressure downhole environment places extremely high requirements on the performance of optical fibers. Stainless steel metal tubes can prevent optical fibers from being damaged in such harsh environments, ensuring the accurate transmission of monitoring data and guaranteeing production safety.

3. Demand for 5G Base Stations and Submarine Cables:The rapid development of 5G technology places higher requirements on communication infrastructure. 5G base stations need a large number of high speed and stable optical fibers for data transmission. At the same time, as an important hub for global communication, submarine cables have more stringent requirements for optical fiber protection. Stainless steel metal tubes are characterized by high strength and corrosion resistance, effectively protecting optical fibers from the influence of the external environment and extending their service life. In the marine environment, the corrosion of seawater and the attachment of marine organisms can cause serious damage to optical fibers. Stainless steel metal tubes can provide reliable protection for optical fibers, ensuring the stable transmission of 5G signals and international communications.

4. Demand for Internal Communication in Data Centers:With the continuous expansion of data center scale and the sharp increase in data processing volume, the demand for high speed fiber - optic communication within data centers is also growing. Between servers, storage systems, and network devices in data centers, a large number of optical fibers are required for high speed data transmission. Metal sheaths can reduce external interference, improving the stability and reliability of data transmission. Additionally, fiber - optic cables with metal sheaths have good heat dissipation performance, which helps to reduce the energy consumption of data centers and improve operational efficiency.

Growth Opportunities:

1. Demand from New Energy Monitoring Systems:The new energy industry, such as wind power and photovoltaics, has developed rapidly in recent years. In wind - power and photovoltaic power plants, real - time monitoring of equipment operating status and environmental parameters is required to ensure power generation efficiency and equipment safety. Fiber optic sensing technology has advantages such as high precision and anti interference, making it suitable for new - energy monitoring systems. Optical fibers in stainless - steel metal tubes have strong weather resistance and can work stably in various harsh natural environments. For example, in an offshore wind farm, the harsh environment of sea wind, waves, and salt spray places high requirements on monitoring equipment. Optical fibers in stainless - steel metal tubes can effectively protect optical fibers from these environmental factors, ensuring the accurate transmission of monitoring data.

2. Application of New Type Stainless Steel Alloys:New type stainless steel alloys, such as 316L and titanium - alloy coatings, have better corrosion resistance and flexibility. The 316L stainless - steel alloy contains molybdenum, which can improve its corrosion resistance in harsh environments and is suitable for more application scenarios. Titanium alloy coatings can further enhance the wear resistance and corrosion resistance of stainless steel metal tubes, while improving their flexibility, making optical fibers less likely to be damaged during bending and twisting. The application of these new materials can expand the application scope of optical fibers in stainless - steel metal tubes, for example, in some complex industrial pipelines and narrow spaces.

3. Increased Demand from Data Center Projects:The implementation of data center projects such as the "Eastern Data, Western Computing" initiative has significantly increased the demand for high - reliability optical fibers. Data centers need a large number of optical fibers for internal and external data transmission to meet the needs of cloud computing, big data, and other services. Optical fibers in stainless steel metal tubes can provide reliable data transmission guarantees, reducing data loss and latency and improving the operational efficiency of data centers. Moreover, as data centers continue to be upgraded and expanded, the requirements for the performance and quality of optical fibers are getting higher and higher. Optical fibers in stainless steel metal tubes are expected to gain wider application in the data center market.

Main Barriers:

1 Main Hindering Factors

1. Cost Difference Leading to the Choice of Alternative Solutions:The manufacturing cost of optical fibers in stainless steel metal tubes is relatively high. Compared with ordinary PVC or loose tube optical fibers, the price is much more expensive. For some small and medium sized enterprises, cost is an important consideration when choosing optical fiber products. To reduce production costs, these enterprises may choose cheaper alternative solutions, thus limiting the development of the market for optical fibers in stainless steel metal tubes. For example, some small communication enterprises may prefer to choose lower priced PVC optical fibers rather than optical fibers in stainless steel metal tubes when building local area networks.

2. Impact of Raw - Material Price Fluctuations:The production of stainless steel metal tubes requires raw materials such as nickel and chromium, and the prices of these raw materials fluctuate greatly. When the prices of raw materials rise, the production cost of stainless steel metal tubes will also increase accordingly, leading to an increase in the price of optical fibers in stainless - steel metal tubes. This not only affects the profit margins of enterprises but also reduces the market competitiveness of products. For example, a significant increase in the price of nickel will greatly increase the production cost of stainless steel metal tubes, and enterprises may face the dilemma of raising product prices or reducing profits.

3. Competition from Carbon Fiber Composite Materials:Carbon fiber composite materials have characteristics such as high strength and light weight, and may replace stainless steel in some high strength and light weight applications. In some aerospace and high end manufacturing industries, the requirements for the strength and weight of materials are extremely high, and carbon fiber composite materials can provide better performance. For example, in the structural components of aircraft, carbon fiber composite materials can reduce the weight of the aircraft and improve flight performance. Therefore, in these fields, carbon fiber composite materials may pose certain competition to optical fibers in stainless steel metal tubes.

Globally, the core manufacturers of optical fiber in stainless steel tube include Hengtong Group, Prysmian Group, Jiangsu Tongguang Electronic Wire and Cable, Yangtze Optical Fibre and Cable Joint Stock Limited Company, AFL, etc. The market is mainly distributed in Europe and the United States, and the Asia-Pacific region with China accounting for the main share. Among them, the top five manufacturers account for approximately 54.47% of the market share.

About The Authors

Huajie Dai |

Email: daihuajie@qyresearch.com |

QYResearch Guangzhou Branch Analyst, as a member of QYResearch Semiconductor Equipment and Materials Department, mainly researches in the fields of electronics, semiconductor equipment, materials, etc. Some of the sub-research topics include automated CNC machine tools, industrial laser equipment, servo drive robots, high-performance servo motors, etc. At the same time, he is also engaged in the development of market segmentation reports and participates in the writing of customized projects. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.