Right Now

Tunnel Lining Segment Molds Market Report: the market size is projected to grow from USD 188.44 million in 2024 to USD 217.52 million by 2031

Tunnel Lining Segment Molds are specialized, precision-engineered forms used in the manufacturing of concrete segments for tunnel linings. These moulds are integral to the production of the curved, modular components that make up the structural lining of tunnels built using tunnel boring machines (TBMs). Designed to ensure uniformity and dimensional accuracy, the moulds are typically made from robust materials like steel and can include features for reinforcing, sealing, and handling the segments. They allow for efficient, high-quality production in precast facilities, ensuring the segments meet the stringent standards required for tunnel construction.

Tunnel Lining Segment Molds Market Summary

Research Background:

The Tunnel Lining Segment Molds market has experienced significant growth in recent years, driven by the expanding demand for underground infrastructure projects, particularly in urban environments and transportation networks. Tunnel Lining Segment Molds are critical components in the construction of tunnels, primarily used to create precast concrete segments that form the structural framework of tunnels. These moulds ensure precision and efficiency in the manufacturing process, leading to faster construction times and cost savings. The rise of large-scale tunneling projects, including metro systems, highways, and utility tunnels, has been a major factor in increasing the adoption of advanced mould technologies. Furthermore, innovations in mould design, automation, and material optimization are propelling market expansion. Key players in the market are focusing on developing customizable, durable, and easy-to-maintain moulds to cater to the growing demand for high-quality, robust tunnel structures. As global urbanization continues to rise, the Tunnel Lining Segment Molds market is expected to see sustained demand, with future trends pointing toward greater automation and integration with digital technologies such as 3D modeling and precision casting.

Development Status:

The development of the Tunnel Lining Segment Molds market has been characterized by continuous advancements in mould technology, with an increasing emphasis on efficiency, durability, and cost-effectiveness. Key trends include the integration of automation and robotics into mould production, which has streamlined manufacturing processes and reduced lead times. Furthermore, the adoption of 3D modeling and computer-aided design (CAD) has enhanced the precision and customization of Tunnel Lining Segment Molds, enabling manufacturers to produce moulds tailored to specific project requirements. These technological improvements have contributed to greater quality control, reduced material wastage, and improved overall productivity. The market is also witnessing the emergence of innovative materials such as high-strength steel alloys and advanced composites, which are being incorporated into mould designs to enhance their longevity and resistance to wear. Despite these advancements, the market faces challenges, including the high initial investment required for state-of-the-art mould production and the complex regulatory environment surrounding construction and safety standards. However, the market continues to evolve with the ongoing growth of tunneling projects worldwide, particularly in rapidly developing regions such as Asia-Pacific, where urbanization and infrastructure development are driving demand for more efficient tunneling solutions.

Future Trends:

Geographic Expansion and Emerging Markets: As infrastructure development accelerates in emerging economies, particularly in the Asia-Pacific region, the demand for Tunnel Lining Segment Molds will grow. These regions, where large-scale urbanization and transportation projects are underway, will become key markets. This trend will drive innovation in mould production techniques and increase competition among manufacturers to meet the unique demands of these rapidly developing areas.

Advanced Materials for Enhanced Durability: The use of advanced, high-performance materials, such as composite alloys and heat-resistant steels, will become more prevalent. These materials will enhance the longevity of moulds, reduce maintenance costs, and improve their resistance to the harsh conditions often encountered in tunnel construction, including exposure to water, chemicals, and high pressure.

Customization and Versatility: With increasing demand for tailored tunneling solutions, future Tunnel Lining Segment Molds will be designed for more flexibility and adaptability to different project needs. Manufacturers will focus on creating modular, adjustable moulds that can be easily modified for various tunnel sizes and shapes, reducing the need for entirely new moulds for every project.

SWOT Analysis:

l Strengths

High Demand from Infrastructure Projects: The growing number of large-scale urban development, transportation networks, and public infrastructure projects (such as metro systems and highways) is driving steady demand for Tunnel Lining Segment Molds.

Durability and Reliability: Tunnel Lining Segment Molds are designed to withstand harsh conditions and heavy wear, ensuring a long lifecycle and reliable performance in demanding tunneling projects.

Cost Efficiency: Precast concrete segments produced with these moulds can help save both time and money by speeding up the construction process compared to traditional in-situ methods.

l Weaknesses

Maintenance and Repair Costs: Even though moulds are durable, they require regular maintenance, and repair or replacement costs can be significant, especially in highly demanding tunneling projects.

Limited Market Penetration in Smaller Regions: While demand is strong in developed markets, the adoption of advanced mould technology may be slower in emerging or less-developed regions due to financial and technical constraints.

Regulatory Barriers: Stringent construction and safety standards, particularly in the tunneling industry, can slow down the market’s growth by complicating the manufacturing process and increasing compliance costs.

l Opportunities

Expansion in Emerging Markets: Rapid urbanization and infrastructure development in regions like Asia-Pacific, the Middle East, and Africa present significant growth opportunities for tunnel segment mould manufacturers.

Customization and Modular Solutions: The growing trend towards customized solutions for specific tunneling projects offers opportunities for manufacturers to create modular, adaptable moulds, allowing for greater versatility and reducing the need for new moulds on every project.

Collaborations and Partnerships: Strategic partnerships with construction firms, tunnel boring machine manufacturers, and infrastructure developers could drive market growth by ensuring better alignment between mould designs and tunneling needs.

l Threats

Intense Competition: The tunnel segment mould market is becoming increasingly competitive, with multiple players vying for market share. Price wars and the pressure to innovate can erode profit margins.

Technological Obsolescence: Rapid technological advancements in mould design and production could make existing moulds obsolete, forcing manufacturers to continuously innovate or risk losing relevance in the market.

Fluctuating Raw Material Prices: The cost of materials such as steel, concrete, and composite alloys, which are essential for mould production, can be volatile, affecting profit margins and production costs.

Economic Downturns and Construction Slowdowns: Global economic uncertainties, such as recessions or changes in government spending on infrastructure, could slow down large-scale construction projects, directly affecting the demand for Tunnel Lining Segment Molds.

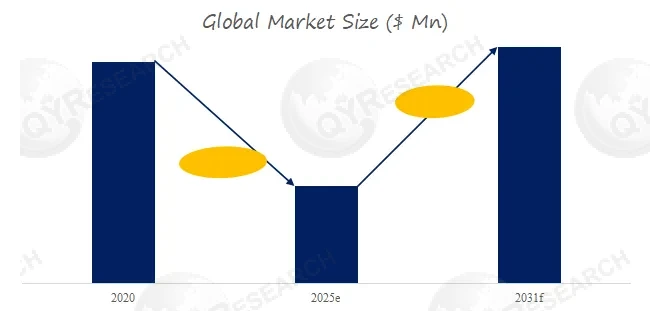

According to the new market research report "Tunnel Lining Segment Molds - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031", published by QYResearch, the global Tunnel Lining Segment Molds market size is projected to grow from USD 188.44 million in 2024 to USD 217.52 million by 2031, at a CAGR of 2.87% during the forecast period.

Figure00001. Global Tunnel Lining Segment Molds Market Size (US$ Million), 2020-2031

Source: QYResearch, "Tunnel Lining Segment Molds - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

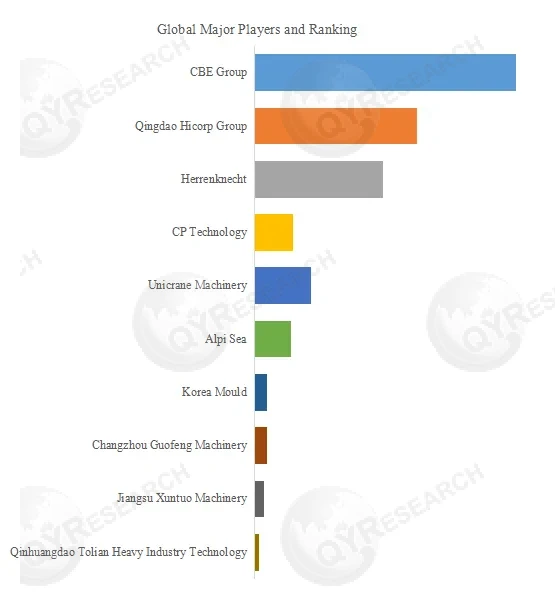

Figure00002. Global Tunnel Lining Segment Molds Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Tunnel Lining Segment Molds - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

This report profiles key players of Tunnel Lining Segment Molds such as CBE Group, Qingdao Hicorp Group, Herrenknecht, etc. In 2024, the global top three players had a share approximately 67.62% in terms of revenue.

In terms of product diameter, currently Below 10m is the largest segment, hold a share of 70.88%.

In terms of product application, currently Subway Tunnels is the largest segment, hold a share of 61.49%.

About The Authors

| Feiya Yu - Lead Author Email: yufeiya@qyresearch.com Feiya Yu is an experienced industry analyst who focuses on the pharmaceutical, mechanical equipment and other industries. She has a keen insight into the development trends, market changes and competitive landscape of the relevant fields of the industry chain. The leading projects include global and Chinese market research on targeted drugs for allergic diseases, esophageal temperature management systems, and lentivirus production systems. Feiya Yu has solid data analysis and market research skills. She can collect and interpret a large amount of industry data through public data sources, field surveys, telephone interviews and other channels to provide accurate market insights and forecasts. She is also good at using various research methods and tools, such as SWOT analysis, PESTEL analysis, competitive analysis, etc., to evaluate the current status and future development trends of the industry and provide reliable reference opinions for corporate decision-making. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.