Right Now

Metal Additive Manufacturing Materials Research: CAGR of 15.6% during the forecast period

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report “Metal Additive Manufacturing Material- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”. Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2025-2031), this report provides a comprehensive analysis of the global Wire Drawing Dies market, including market size, share, demand, industry development status, and forecasts for the next few years.

The global market for Metal Additive Manufacturing Material was estimated to be worth US$ 375 million in 2024 and is forecast to a readjusted size of US$ 591 million by 2031 with a CAGR of 6.8% during the forecast period 2025-2031.

【Get a free sample PDF of this report (Including Full TOC, List of Tables & Figures, Chart)】

https://www.qyresearch.com/reports/4441675/metal-additive-manufacturing-material

Metal Additive Manufacturing Materials Market Summary

Metal additive manufacturing materials refer to the raw materials used in metal 3D printing processes, typically in the form of metal powder or filament. Their core characteristic is the direct conversion from digital models to physical entities, achieved through a computer-controlled layer-by-layer melting/deposition process based on the "discrete-accumulation" principle to build three-dimensional solid parts.

According to the new market research report “Global Metal Additive Manufacturing Materials Market Report 2025-2031”, published by QYResearch, the global Metal Additive Manufacturing Materials market size is projected to reach USD 3.08 billion by 2031, at a CAGR of 15.6% during the forecast period.

Figure00001. Global Metal Additive Manufacturing Materials Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch: Global Metal Additive Manufacturing Materials Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

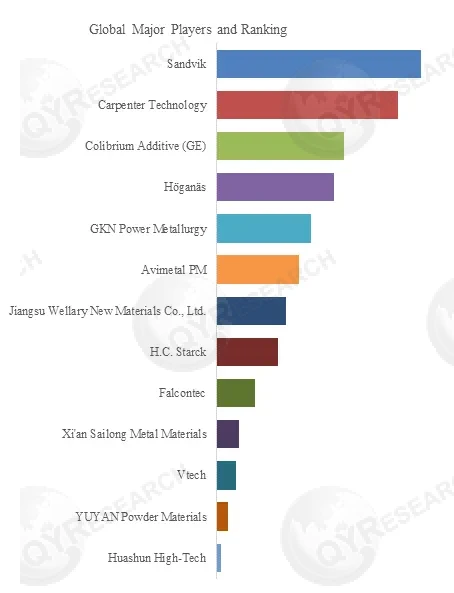

Figure00002. Global Metal Additive Manufacturing Materials Top 13 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Above data is based on report from QYResearch: Global Metal Additive Manufacturing Materials Market Report 2025-2031 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Metal Additive Manufacturing Materials include Sandvik, Carpenter Technology, Colibrium Additive (GE), Höganäs, GKN Power Metallurgy, etc. In 2024, the global top five players had a share approximately 39.0% in terms of revenue.

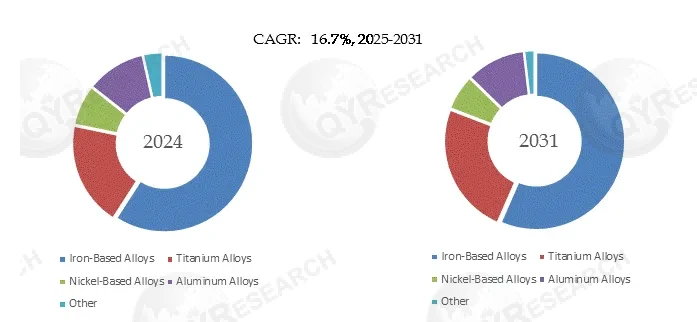

Figure00003. Metal Additive Manufacturing Materials, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Metal Additive Manufacturing Materials Market Report 2025-2031.

Metal Additive Manufacturing Materials: A New High-End Manufacturing Track Driven by Technological Revolution

The metal additive manufacturing materials industry is reshaping the manufacturing paradigm in aerospace, medical implants, and automotive lightweighting, driven by technological breakthroughs. Essentially, metal additive manufacturing (AM) involves layering metal powder or wire into complex structural components through techniques like powder bed fusion (PBF) and directed energy deposition (DED), enabling lightweight, integrated designs that are difficult to achieve with traditional processes. Currently, the industry's technological path is evolving from single-material to multi-material, high-performance technologies. Core materials such as titanium alloys, high-temperature alloys, and stainless steel have significantly improved their mechanical properties and printing reliability through process upgrades like particle size optimization and oxygen content control. This technological evolution not only meets the aerospace industry's demand for high-strength and heat-resistant components, but also promotes the mass adoption of personalized implants in the medical industry, forming a closed-loop innovation ecosystem encompassing "materials, processes, and applications." Market Dynamics and Growth Logic: Demand Upgrade and Policy Resonance

Upgraded market demand has become the core driver of industry growth. In the aerospace sector, customized demand for complex metal components, from engine blades to satellite structures, has surged. In the medical field, 3D-printed orthopedic implants have seen increasing clinical penetration year by year due to their biocompatibility and personalized fit. In the automotive industry, the trend toward lightweighting new energy vehicles has seen the gradual adoption of metal additive manufacturing in components such as battery cases and motor housings. On the policy front, the government, through documents such as the "14th Five-Year Plan for Intelligent Manufacturing Development," has designated additive manufacturing as a key technological development area, encouraging companies to overcome bottlenecks in domestic material production. At the same time, capital market attention to the industry has significantly increased. Research reports from leading brokerages indicate that by 2025, the metal additive manufacturing materials sector, supported by favorable policies and liquidity, is expected to see both performance and valuation increases. Companies with technological advantages, in particular, are leveraging industry-university-research collaborations to deepen their ties with end users and capture the high-end market. Business Outlook: Technological Barriers, Deepening Application Scope, and Ecosystem Building

Leading companies are consolidating their competitive advantages through three main approaches: First, breakthroughs in material performance. For example, Polylite and Farsoon High-Tech have developed customized materials such as high-strength titanium alloys and high-temperature-resistant nickel-based alloys through optimized powder preparation processes, building a patent moat. Second, scenario-based solutions are shifting from single-material supply to a "material + process + service" offering. For example, they provide aerospace customers with ultra-thin-wall structural part printing solutions, or provide medical companies with full-process support from design to clinical validation. Third, global ecosystem collaboration. Leading companies are expanding into the international aerospace and medical markets by establishing overseas R&D centers or strategically collaborating with multinational giants. Furthermore, the integration of artificial intelligence and simulation technologies is fostering a digital closed loop of "materials-design-manufacturing." For example, AI-powered predictions of material properties shorten R&D cycles.

Future Outlook: Industry Restructuring Driven by Innovation

The future of the metal additive manufacturing materials industry belongs to those companies that can transform technological breakthroughs into application-specific value. With the maturity of technologies such as multi-material printing and ultra-high-speed deposition, the boundaries of industry applications will continue to expand. Companies need to leverage "technology + scenarios + ecosystem" as their strategic fulcrum, delving deeply into key sectors like aerospace, healthcare, and automotive. Simultaneously, through global expansion and ecosystem collaboration, they can upgrade from "material suppliers" to "leaders of high-end manufacturing solutions." In this process, those that consistently innovate and accurately understand customer needs will seize the initiative in this technology-driven industrial transformation.

The Metal Additive Manufacturing Material market is segmented as below:

By Company

Sandvik

Carpenter

GE

Sai Long Metal

H.C. Starck

Material Technology Innovations

Avimetal PM

Höganäs

Falcontec

Erasteel

Vtech

Yu Guang Phelly

GKN Power Metallurgy

Asia-General

Bao Hang Advanced Materials

Segment by Type

Aluminum Alloy

Titanium Alloy

Nickel Alloy

Stainless Steel

Other

Segment by Application

Healthcare

Aerospace & Defense

Automotive

Others

Each chapter of the report provides detailed information for readers to further understand the Metal Additive Manufacturing Material market:

Chapter 1: Introduces the report scope of the Metal Additive Manufacturing Material report, global total market size (valve, volume and price). This chapter also provides the market dynamics, latest developments of the market, the driving factors and restrictive factors of the market, the challenges and risks faced by manufacturers in the industry, and the analysis of relevant policies in the industry. (2020-2031)

Chapter 2: Detailed analysis of Metal Additive Manufacturing Material manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc. (2020-2025)

Chapter 3: Provides the analysis of various Metal Additive Manufacturing Material market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments. (2020-2031)

Chapter 4: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.(2020-2031)

Chapter 5: Sales, revenue of Metal Additive Manufacturing Material in regional level. It provides a quantitative analysis of the market size and development potential of each region and introduces the market development, future development prospects, market space, and market size of each country in the world..(2020-2031)

Chapter 6: Sales, revenue of Metal Additive Manufacturing Material in country level. It provides sigmate data by Type, and by Application for each country/region.(2020-2031)

Chapter 7: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc. (2020-2025)

Chapter 8: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 9: Conclusion.

Benefits of purchasing QYResearch report:

Competitive Analysis: QYResearch provides in-depth Metal Additive Manufacturing Material competitive analysis, including information on key company profiles, new entrants, acquisitions, mergers, large market shear, opportunities, and challenges. These analyses provide clients with a comprehensive understanding of market conditions and competitive dynamics, enabling them to develop effective market strategies and maintain their competitive edge.

Industry Analysis: QYResearch provides Metal Additive Manufacturing Material comprehensive industry data and trend analysis, including raw material analysis, market application analysis, product type analysis, market demand analysis, market supply analysis, downstream market analysis, and supply chain analysis.

and trend analysis. These analyses help clients understand the direction of industry development and make informed business decisions.

Market Size: QYResearch provides Metal Additive Manufacturing Material market size analysis, including capacity, production, sales, production value, price, cost, and profit analysis. This data helps clients understand market size and development potential, and is an important reference for business development.

Other relevant reports of QYResearch:

Global Metal Additive Manufacturing Material Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Global Metal Additive Manufacturing Material Market Research Report 2025

Global Metal Materials for Additive Manufacturing Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Global Metal Materials for Additive Manufacturing Market Research Report 2025

Metal Materials for Additive Manufacturing- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

Global Metal Material Based Additive Manufacturing Sales Market Report, Competitive Analysis and Regional Opportunities 2025-2031

Metal Material Based Additive Manufacturing- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

Global Metal Material Based Additive Manufacturing Market Research Report 2025

Additive Manufacturing Metal Printing Material- Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031

Global Additive Manufacturing Metal Printing Material Market Research Report 2025

About Us:

QYResearch founded in California, USA in 2007, which is a leading global market research and consulting company. Our primary business include market research reports, custom reports, commissioned research, IPO consultancy, business plans, etc. With over 18 years of experience and a dedicated research team, we are well placed to provide useful information and data for your business, and we have established offices in 7 countries (include United States, Germany, Switzerland, Japan, Korea, China and India) and business partners in over 30 countries. We have provided industrial information services to more than 60,000 companies in over the world.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.