Right Now

Understanding Industrial Motors and their

Importance

AC

Motors

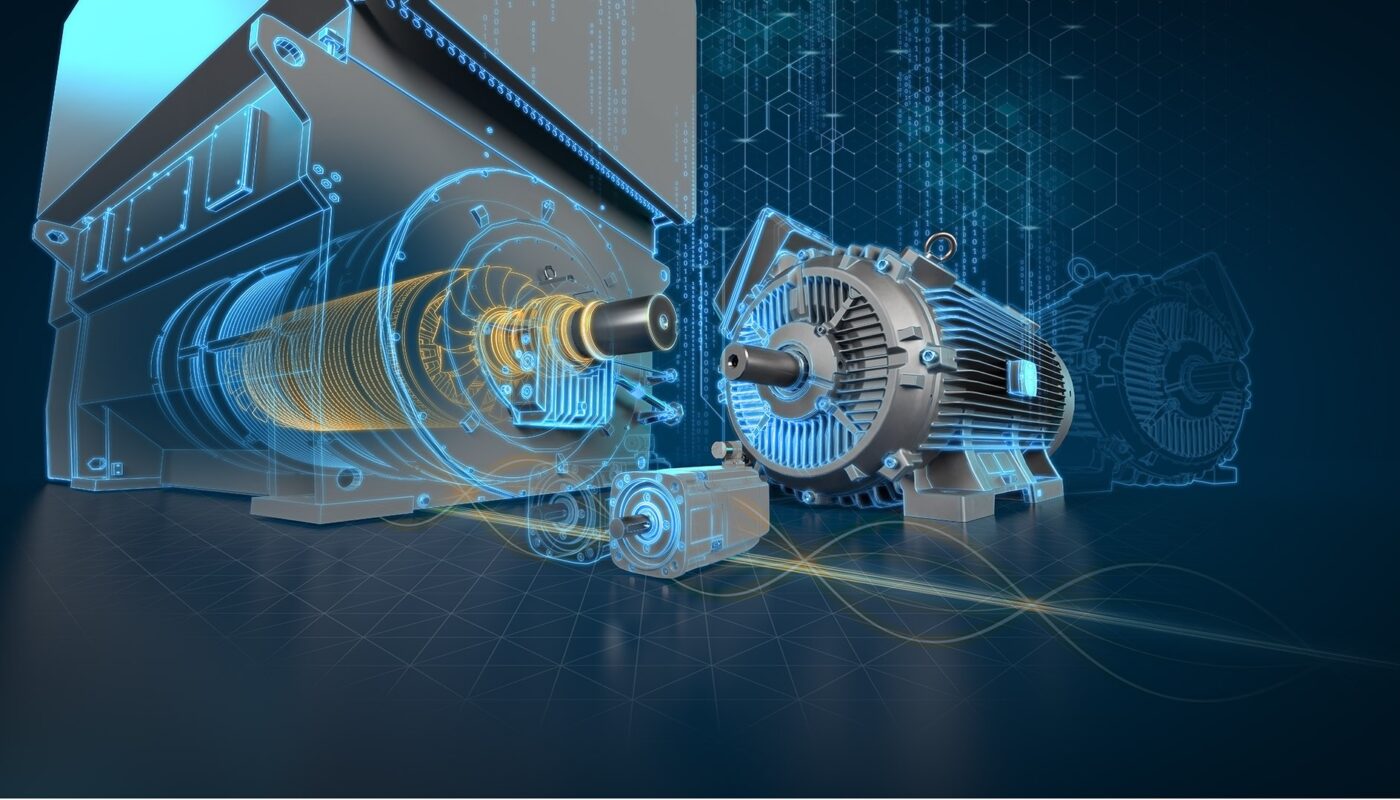

Alternating current (AC) motors are one of the most common types of industrial

motors used across various industries. AC motors work on alternating current

and have properties such as easy speed control, high starting torque, overload

capacity, etc. Some common types of AC motors include induction motors,

synchronous motors, and servo motors. Induction motors are the most widely used

AC motor due to their simple and robust construction, low cost of maintenance,

and ability to start under load. They find applications in equipment requiring

continuous speed regulation like assembly lines, pumps, conveyors, etc.

Synchronous motors are designed for applications requiring precise speed

synchronism like CNC machines.

DC Motors

Direct current (DC) motors operate using direct current power sources like

batteries. Some key characteristics of Industrial

Motors include high starting torque, ability of speed and torque

control, and ability to work in either direction by reversing the current flow.

DC motors mainly find usage where variable or reversible speed control is

important such as in robotics, fluid couplings, printing machines, elevators,

etc.

Common

DC motor types include brushed DC motors and brushless DC motors. Brushed DC

motors have commutator and brushes to carry current to the rotor. Brushless DC

motors have replaced brushes with solid-state electronic switches thereby

eliminating brush and commutation problems.

Get

More Insights On, Industrial

Motors

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.