Right Now

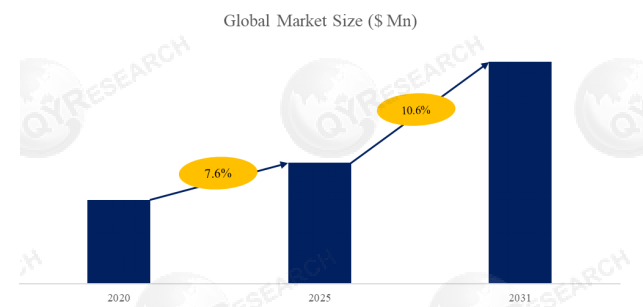

CO2 Compressor for CCUS Research:CAGR of 10.6% during the forecast period (2025-2031)

CO2 Compressor for CCUS Market Summary

CO2 Compressor for CCUS is key devices in carbon capture systems used to compress and transport captured carbon dioxide. They compress the captured CO2 gas to high pressure for subsequent storage or transportation. CO2 Compressor for CCUS typically employ high-performance compression technologies and sealing designs to ensure long-term stable operation under high-pressure, high-temperature, and corrosive gas environments.

Additionally, these devices feature energy efficiency, ease of maintenance, and intelligent control, enabling precise adjustment of compression ratios and output power according to actual needs. By optimizing the compression process, CO2 Compressor for CCUS reduces energy consumption and emissions, contributing to enhanced overall performance and cost reduction of carbon capture systems.

According to the new market research report "Global CO2 Compressor for CCUS Market Report 2025-2031", published by QYResearch, the global CO2 Compressor for CCUS market size is projected to grow from USD 937.06 million in 2024 to USD 1,823.96 million by 2031, at a CAGR of 10.6% during the forecast period (2025-2031).

Figure00001. Global CO2 Compressor for CCUS Market Size (US$ Million), 2020-2031

Above data is based on report from QYResearch: Global CO2 Compressor for CCUS Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

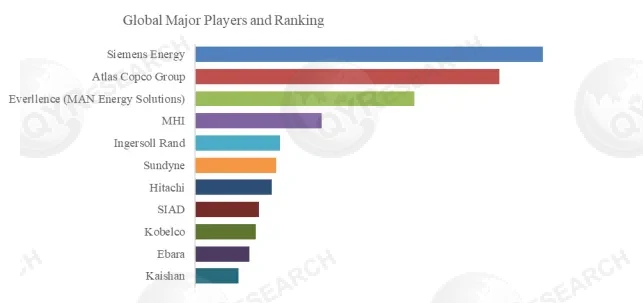

Figure00002. Global CO2 Compressor for CCUS Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Above data is based on report from QYResearch: Global CO2 Compressor for CCUS Market Report 2025-2031 (published in 2025). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of CO2 Compressor for CCUS include Siemens Energy, Atlas Copco Group, Everllence (MAN Energy Solutions), MHI, Ingersoll Rand, Sundyne, Hitachi, SIAD, Kobelco, Ebara, etc. In 2024, the global top 10 players had a share approximately 82.0% in terms of revenue.

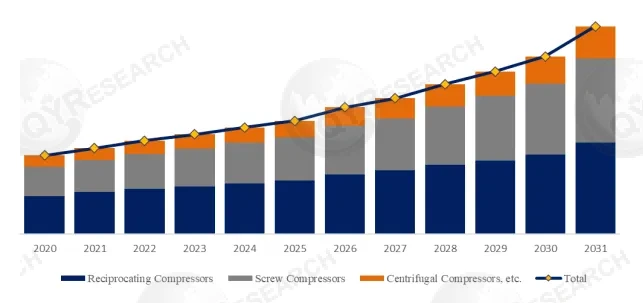

Figure00003. CO2 Compressor for CCUS, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global CO2 Compressor for CCUS Market Report 2025-2031.

In terms of product type, currently Reciprocating Compressors is the largest segment, hold a share of 47.5%.

In terms of product application, currently Power Generation is the largest segment, hold a share of 53.8%.

CO2 Compressor for CCUS Market Trends

Customization and integration become the mainstream technology: The CO2 Compressor for CCUS market is showing significant customized demand characteristics. Different industrial scenarios have put forward differentiated requirements for the pressure level, gas handling capacity and system compatibility of the compressor. This has prompted manufacturers to develop modular product platforms, achieve rapid configuration through standardized interfaces, and optimize performance by combining digital twin technology, so that a single device can adapt to a variety of carbon capture environments from chemical plants to power plants. Integrated solutions have gradually become the industry standard, which packages compression units with pretreatment, cooling and control systems, significantly reducing engineering complexity and shortening project delivery cycles.

Policy incentives drive global market expansion: Against the backdrop of global carbon neutrality, policy support from various countries has become a key driving force for the development of the CO2 Compressor for CCUS market. Europe and the United States stimulate investment through tax credits and carbon pricing mechanisms; the Asia-Pacific region promotes the construction of demonstration projects through industrial policies. This policy orientation has accelerated the deployment of carbon capture facilities in energy-intensive industries, directly driving the demand for high-performance compressors.

Breakthrough progress in energy efficiency improvement technology: The new generation of CO2 Compressor for CCUSs is achieving a leap in energy efficiency through multi-dimensional innovation, including the use of three-dimensional flow impeller design to increase isentropic efficiency to more than 88%, the application of magnetic bearings to reduce mechanical losses, and the development of adaptive control systems to adjust operating parameters in real time according to load. These technological advances have reduced the proportion of energy consumption in the compression link and greatly improved the economic efficiency of CCUS projects. At the same time, the predictive maintenance system based on the Internet of Things improves the availability of equipment through multi-parameter monitoring such as vibration and temperature, providing reliable guarantees for large-scale commercial operations.

CO2 Compressor for CCUS Market Drivers

Policy Support: Increasingly stringent environmental regulations and carbon neutrality targets around the world are driving high-emission industries to accelerate the deployment of carbon capture systems, directly driving the market demand for CO2 Compressor for CCUSs.

Demand Expansion: With the increasing pressure on emission reduction in high-emission industries such as electricity, steel, and chemicals, and the development of emerging direct air capture technologies, the market demand for CO2 Compressor for CCUSs continues to grow, driving the product to develop in a diversified and professional direction.

Technological Innovation: The continuous breakthroughs in the application of new materials, intelligent control systems, and high-efficiency designs have significantly improved the performance and adaptability of CO2 Compressor for CCUSs to working conditions, providing technical support for large-scale commercial applications.

CO2 Compressor for CCUS Market Restraints

Policy Uncertainty: The commercialization of carbon capture technology is highly dependent on government subsidies and carbon pricing mechanisms, but the intensity and sustainability of policy support in various countries are uncertain. If emission reduction policies are relaxed or incentives are reduced, it will directly affect the market demand and investment returns of CO2 Compressor for CCUSs.

Reliability Risk: CO2 Compressor for CCUSs need to operate in high-pressure and corrosive environments for a long time, and the technical maturity still faces challenges. If the performance of key materials (such as corrosion-resistant alloys) or core components (such as sealing systems) does not meet the standards, it may lead to an increase in equipment failure rates, increase operation and maintenance costs, and affect the economic viability of the project.

Market Demand Fluctuations: The demand for CO2 Compressor for CCUSs is closely related to the progress of industrial emission reduction. If the transformation of high-emission industries slows down or alternative technologies (such as green hydrogen) are popularized more quickly, market growth expectations may be weakened. In addition, regional development imbalances may also lead to problems of overcapacity or local supply shortages.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

EN: https://www.qyresearch.com

Email: global@qyresearch.com

Tel: 001-626-842-1666(US)

JP: https://www.qyresearch.co.jp

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.