Right Now

Confectionery Processing Equipment Market Demand and Key Players: [Insights and Forecast]

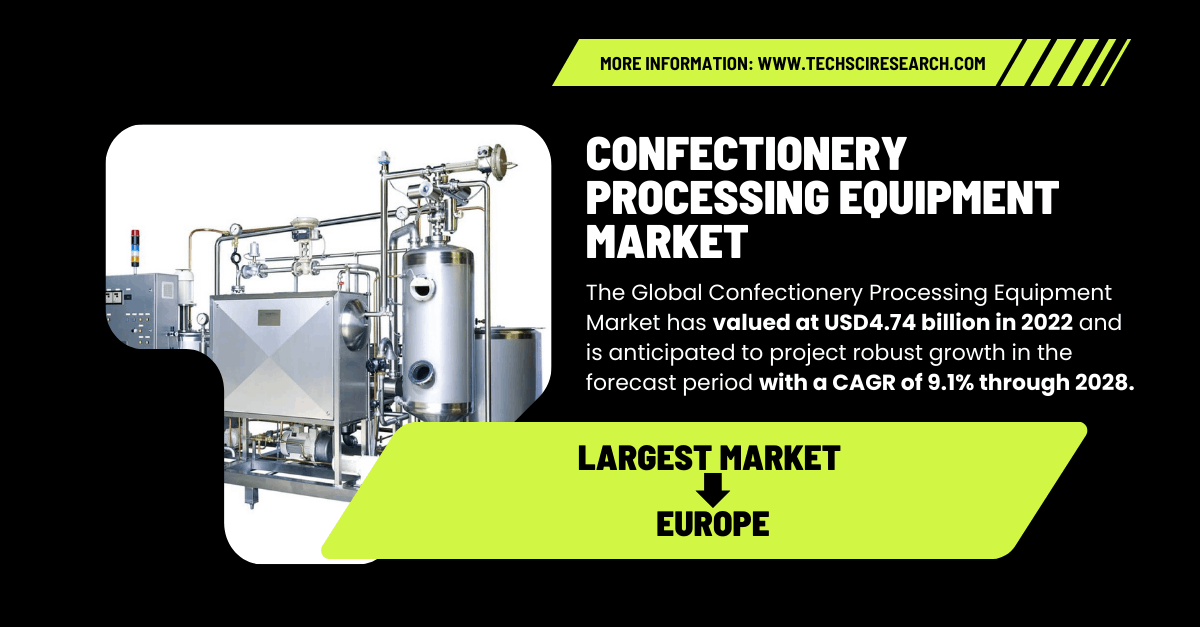

The Global Confectionery Processing Equipment Market was valued at USD 4.74 billion in 2022 and is anticipated to experience robust growth with a CAGR of 9.1% through 2028.

The confectionery industry, driven by consumer indulgence, seasonal celebrations, and cultural traditions, relies on sophisticated machinery and technology to transform raw ingredients into a diverse array of sweets, including chocolates, candies, pastries, and gummies. The rising popularity of gourmet and artisanal confections, alongside advancements in food processing technology, continues to propel market expansion.

Confectionery Processing Equipment Market Overview

The confectionery processing equipment sector is a crucial and growing segment within the broader food processing industry. This market includes a wide range of equipment such as mixers, tempering machines, enrobers, molding equipment, cooling tunnels, and packaging systems.

The increasing global demand for confectionery products, driven by factors such as urbanization, rising disposable incomes, and changing consumer lifestyles, continues to fuel the need for efficient and versatile equipment. Moreover, technological advancements are making these machines more precise, cost-effective, and energy-efficient, further encouraging manufacturers to invest in modern processing solutions.

Key Trends in Confectionery Processing Equipment Market

- Evolving Consumer Preferences

Consumer tastes are constantly evolving, emphasizing premium quality, innovative flavors, and personalized experiences. The demand for organic, plant-based, and functional confectionery items is on the rise, prompting manufacturers to invest in state-of-the-art processing equipment capable of handling alternative ingredients. Additionally, seasonal and limited-edition confections are becoming increasingly popular, requiring flexible machinery that can accommodate small-batch and custom production runs.

Browse over XX market data Figures spread through XX Pages and an in-depth TOC on the "Global Confectionery Processing Equipment Market.” @ https://www.techsciresearch.com/report/confectionery-processing-equipment-market/3654.html

- Technological Advancements in Equipment

Automation, precision control, and the integration of smart technologies have revolutionized the confectionery processing equipment landscape. Advanced machinery equipped with robotics, IoT connectivity, and AI-driven monitoring systems enhances efficiency, reduces production downtime, and ensures product consistency. These technological advancements enable manufacturers to produce large volumes of confections while maintaining high standards of quality, hygiene, and safety. Furthermore, innovations such as 3D food printing are opening new possibilities for custom confectionery designs and intricate product textures.

- Health-Conscious Innovations

With increasing health awareness, manufacturers are exploring reduced-sugar confections, natural sweeteners, and functional additives such as vitamins, probiotics, and protein fortification. This shift necessitates equipment that can accommodate these innovative ingredients without compromising on taste and quality. Additionally, the rise of allergen-free and gluten-free confectionery options has led to the development of specialized processing equipment that prevents cross-contamination while maintaining production efficiency.

- Global Flavor Influence

The interconnectedness of the world has exposed consumers to a variety of global flavors, leading to a greater demand for exotic and internationally inspired confections. As a result, confectionery processing equipment must enable manufacturers to create products that reflect international culinary influences, such as matcha-infused chocolates from Japan, spicy tamarind candies from Latin America, and traditional Middle Eastern halva. This diversity in flavor trends has driven the need for versatile and adaptable processing machines capable of handling various ingredients and production techniques.

Confectionery Processing Equipment Market Segmentations

By Type

The market is segmented based on the type of equipment used in the confectionery production process:

Thermal Equipment – Essential for temperature-sensitive processes such as chocolate tempering and caramelization.

Extrusion Equipment – Used to shape confections like licorice, chewing gum, and soft candies.

Mixers, Blenders & Cutters – Ensure uniform ingredient distribution and precise cutting of confectionery items.

Cooling Equipment – Facilitates rapid cooling of chocolates, gummies, and hard candies to maintain texture and consistency.

Coating Equipment – Applies layers of chocolate, sugar, or other coatings to enhance product appeal and taste.

Other Equipment – Includes molding machines, polishing drums, and packaging systems essential for final product presentation.

Among these, blenders and cutters play a crucial role in ensuring uniform mixtures and precise ingredient processing. These machines are instrumental in achieving desired textures and flavors in confectionery products, allowing for the production of smooth, creamy chocolates, finely ground nut pastes, and evenly distributed fruit fillings. As consumer demand for artisanal and gourmet confections grows, high-performance blending and cutting equipment are becoming increasingly important.

By Mode of Operation

The market is also segmented by the level of automation:

Automatic – Fully automated systems that enhance production efficiency, reduce manual labor, and ensure consistent quality.

Semi-Automatic – Machines that require some human intervention, offering a balance between automation and artisanal craftsmanship.

The automatic segment dominates the market, as automated systems improve efficiency, reduce human errors, and ensure consistent quality. Automation also helps manufacturers meet consumer demands for convenience and customization while reducing production costs. Additionally, automated systems incorporate advanced sensors and real-time monitoring, allowing for greater precision in ingredient dosing, temperature control, and product shaping.

Challenges in the Confectionery Processing Equipment Market

Balancing Automation and Artistry

While automation enhances efficiency, it poses a challenge in preserving the artisanal quality of traditional confectionery. Achieving the right balance between mechanization and handcrafted appeal remains a significant hurdle. Premium chocolate makers, boutique candy producers, and specialty bakeries often seek hybrid solutions that allow for mechanized precision while maintaining handcrafted techniques that contribute to unique textures and flavors.

Regulatory Compliance

The confectionery industry is subject to strict food safety and quality regulations, which vary across regions. Processing equipment must comply with these standards to ensure consumer safety and maintain product integrity. Regulations related to ingredient labeling, contamination prevention, and allergen management require manufacturers to invest in hygienic and easy-to-clean equipment that meets global food safety guidelines, such as those set by the FDA, EU, and ISO standards.

Recent Developments

In 2023, TTK Prestige, a leading appliance manufacturer in India, introduced an advanced kitchen appliance with a 1000W motor featuring ball bearings. This upgrade ensures smoother operation, reduced noise, and minimal vibration, ultimately extending the motor’s lifespan and enhancing performance. Similarly, leading confectionery equipment manufacturers are investing in innovations such as energy-efficient heating systems, high-speed robotic packaging solutions, and smart tracking systems to optimize production.

Download Free Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=3654

Customers can also request 10% free customization on this report.

Key Market Players

Several major companies dominate the Global Confectionery Processing Equipment Market, including:

Baker Perkins – A leader in confectionery and bakery processing solutions, known for innovative molding and depositing systems.

Heat and Control, Inc. – Specializes in cooking, coating, and packaging equipment with advanced automation features.

BCH Ltd. – Renowned for producing high-performance mixing and extrusion systems for confectionery products.

Sollich – A key player in chocolate enrobing and tempering equipment.

Tanis Confectionery – Focuses on gummy and jelly processing solutions with high-precision dosing systems.

Alfa Laval – Offers advanced heat exchangers and hygienic processing equipment for confectionery applications.

JBT Corporation – Provides state-of-the-art solutions for food processing and confectionery manufacturing.

Bosch – Known for automated packaging and processing systems that enhance efficiency and sustainability.

Aasted – Specializes in chocolate molding, tempering, and cooling systems.

Bühler AG – A global leader in food processing equipment, offering cutting-edge solutions for confectionery manufacturing.

Future Outlook

According to industry experts, the Global Confectionery Processing Equipment Market is poised for continuous growth and innovation. Manufacturers that prioritize automation, customization, and health-conscious production practices will gain a competitive edge. As consumer preferences evolve, confectionery processing equipment will play a vital role in delivering innovative and high-quality treats that meet the dynamic demands of global markets. Additionally, the integration of AI-driven predictive maintenance and sustainable production practices is expected to shape the future of the industry.

Conclusion

The Global Confectionery Processing Equipment Market is a dynamic and rapidly expanding sector driven by technological advancements, evolving consumer preferences, and the demand for high-quality confectionery products. With automation, personalization, and health-conscious trends shaping the industry, manufacturers and investors have significant opportunities for growth and innovation in the coming years.

You may also read:

Chocolate Confectionery Market Analysis: USD 185.23 Billion Valuation & 5.2% Growth Rate [Forecast]

Cigarette Market Overview: USD 1205.6 Billion with Projected Robust Growth [CAGR 3.7%]

Cigarette Vending Machine Market Trends: {Key Players}, {Share}, and {Growth Analysis}

Citrus Oil Market Growth Analysis: USD 1.15 Billion & [6.52%] CAGR Projection

Cloud Kitchen Market Size and Forecast: Projected [11%] CAGR Growth

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.