Right Now

3C Coating Analysis Report : the global 3C Coating market size is projected to reach USD 1.28 billion by 2031

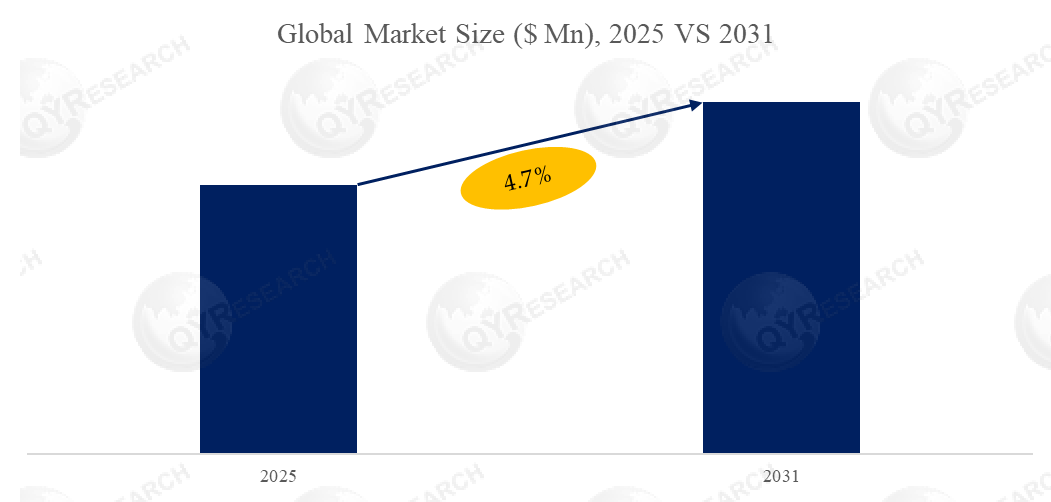

According to the new market research report “3C Coating - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global 3C Coating market size is projected to reach USD 1.28 billion by 2031, at a CAGR of 4.7% during the forecast period.

Figure00001. Global 3C Coating Market Size (US$ Million), 2020-2031

Source: QYResearch, "3C Coating - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

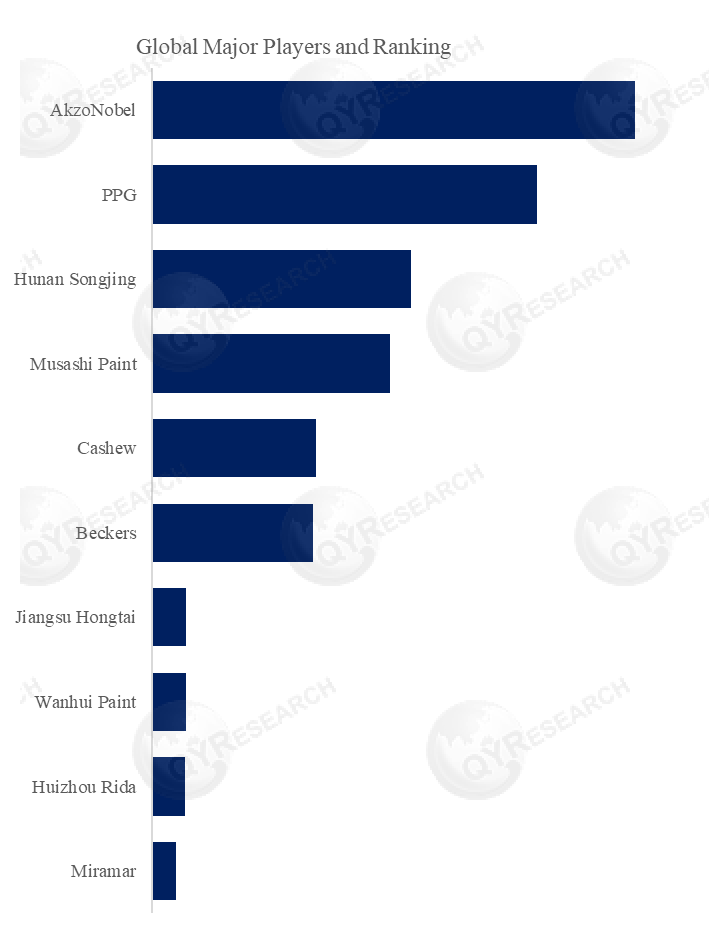

Figure00002. Global 3C Coating Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "3C Coating - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of 3C Coating include AkzoNobel, PPG, Hunan Songjing, Musashi Paint, Cashew, Beckers, Jiangsu Hongtai, Wanhui Paint, Huizhou Rida, Miramar, etc. In 2024, the global top 10 players had a share approximately 60.0% in terms of revenue.

In terms of product type, currently PU Coating is the largest segment, hold a share of 48.3%.

In terms of product application, currently Mobile Phones is the largest segment, hold a share of 54.5%.

Market Drivers:

With the popularity of consumer electronic products such as smartphones, laptops, and wearable devices around the world, the demand for durable, beautiful, and versatile coatings is growing. Coatings play a key role in protecting the surface of electronic devices and improving the appearance and texture, and the market demand for high-performance coatings continues to rise.

In the consumer electronics industry, water-based coating materials are still in their infancy in the field of high-end consumer electronics. As people's environmental awareness and health awareness continue to increase, coupled with the requirements of domestic environmental protection policies, the environmental pressure of traditional oil-solvent coatings is increasing. More terminal brands are beginning to take on social responsibilities in the field of environmental protection and gradually promote and use water-based coatings.

Benefiting from the promotion of environmental protection policies, the 3C coating industry is accelerating its transformation towards low VOC and water-based. It is expected that by 2025, the proportion of water-based 3C electronic coatings will exceed 50%, among which the laptop field will be the first to achieve full water-based, and the water-based process of products such as mobile phones, keyboards and mice will also be rapidly promoted.

With the advancement of technology, 3C coatings are developing in the direction of intelligence and functionality. New coatings have multiple functions such as self-repairing, antibacterial, and anti-fouling. They can automatically adjust according to environmental changes to improve the durability of equipment and user experience. In addition, the application of nanotechnology also enhances the performance of coatings, such as improving wear resistance, corrosion resistance and UV resistance, meeting the needs of electronic products in diverse application scenarios.

Restraint:

3C coating production is highly dependent on raw materials such as solvents, resins, and metallic pigments in the petrochemical industry chain, and the prices of these raw materials are significantly affected by fluctuations in the international crude oil market. In recent years, crude oil prices have continued to fluctuate upward, resulting in rising costs for related raw materials, which has directly pushed up the production costs of coatings. Since 3C coating products are price sensitive, it is difficult to fully pass on cost increases to downstream, which compresses corporate profit margins and increases operating pressure.

The 3C coating industry has a fast technological iteration speed, and products need to constantly adapt to the replacement of terminal equipment. However, there are widespread problems in the industry of insufficient R&D investment and weak accumulation of core technologies, which has led to challenges for companies in technological innovation. In addition, intellectual property protection is difficult, and technological achievements are easily imitated or infringed, which weakens the market competitiveness of companies and restricts the healthy development of the industry.

Opportunity:

In the future, the 3C coating industry will develop towards environmental protection, functionalization and automation. First, environmentally friendly systems such as water-based UV, low-temperature curing, and high-adhesion water-based PU will continue to replace traditional solvent-based coatings and become the mainstream choice for high-end mobile phones and laptops. Against the background of stricter policy supervision and strengthened environmental protection responsibilities of terminal brands, systems with environmentally friendly attributes will gain higher bargaining power and market share. Secondly, the functional market segment will develop rapidly. For example, multifunctional coatings with fingerprint resistance, anti-glare, conductivity, and anti-blue light properties are gradually being widely adopted by emerging electronic products such as folding screens and OLED panels.

The industrial chain will also show a trend of intensive and intelligent development. As Vietnam, India and other places become new manufacturing highlands, international coatings giants are accelerating local deployment to form a "technology output + local delivery" model; while local brands rely on flexible formula customization capabilities and response speed to establish barriers in mid-range models and notebooks. In the future, with the maturity of intelligent manufacturing technologies such as AI quality inspection and automatic spraying systems, the overall process of 3C coatings will become more standardized and controllable. At the same time, the industry structure may further concentrate on the top, and companies with complete product lines and global delivery capabilities will gain a leading advantage in the next round of technological changes and customer integration.

About The Authors

Lu Jing - Lead Author |

Email: lujing@qyresearch.com |

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 10 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.