Right Now

Bag-in-Box Packaging Machine Market Trends: the market size is expected to reach US$3.21 billion in 2031

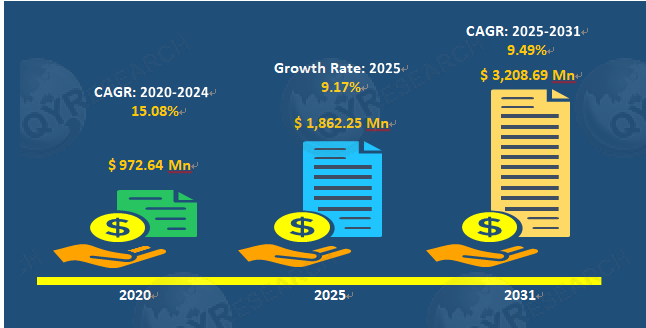

According to the latest report "Bag-in-box Packaging Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031" by the QYResearch research team, the global bag-in-box packaging machine market size is expected to reach US$3.21 billion in 2031, with a compound annual growth rate (CAGR) of 9.49% in the next few years.

Bag-in-box Packing Machine Market Summary

Bag-in-box (BIB) packing machine, a type of filling equipment used to pack liquid products or semi-liquid products into bags in boxes.

Bag-in-box (BIB) packing machines can automatically complete the filling, sealing and capping or accessories insertion processes to ensure accurate dosage, hygienic operation and product protection.

Bag-in-box (BIB) packing machines can operate in non-sterile or sterile (aseptic) environments and can support manual, semi-automatic or fully automatic configurations according to production needs.

Bag-in-box (BIB) packing machines are commonly used in industries such as food and beverage (e.g. wine, juice, dairy products), chemicals and household products because they can maintain product freshness, reduce packaging waste and achieve efficient storage and transportation.

Bag-in-box packaging machines are developing rapidly around the world, and their market trends are mainly driven by green packaging, food safety and distribution efficiency. With the increasing attention paid to environmentally friendly and sustainable packaging forms around the world, BIB (Bag-in-Box) packaging has gradually replaced traditional glass bottles, plastic barrels and other forms with its advantages of less material, recyclability and high transportation efficiency. It is widely used in industries such as juice, dairy products, wine, ketchup and liquid condiments. At the same time, the continuous advancement of intelligent and automated packaging technology has promoted the development of packaging equipment in the direction of multi-function, high speed and low pollution, meeting the production upgrade needs of medium and large liquid production enterprises.

The global bag-in-box packaging machine market is in a period of steady expansion. According to the forecast of market research institutions. North America and Europe are mature markets, and BIB has a high penetration rate in the field of wine and dairy products; while the Asia-Pacific region is the fastest growing region, especially China, India, Indonesia and other countries have grown significantly in application scenarios such as beverage distribution, edible oil packaging and industrial filling. In terms of packaging equipment, the proportion of fully automatic filling equipment has increased year by year, and semi-automatic equipment is widely used in small and medium-sized enterprises, pilot workshops and special liquid processing.

The rapid development of bag-in-box packaging machines is driven by a variety of market drivers. First, with the change in the consumption of liquid food, BIB packaging is being adopted by more and more brands due to its convenience, hygiene and anti-oxidation advantages. Second, companies are paying more and more attention to the goals of "green packaging" and "cost reduction and efficiency improvement". BIB packaging solutions have obvious advantages in transportation, storage and material costs, which can reduce logistics costs by more than 30%. Third, consumers' demand for packaging safety and convenience continues to rise, which also forces brands to update and upgrade packaging forms and production equipment. In addition, the development of automated and intelligent packaging technology has enabled the deep integration of packaging machines and digital control systems, greatly improving production line efficiency and cleaning convenience.

Although the overall growth trend of the bag-in-box packaging machine market is good, it still faces multiple challenges. First, the initial investment of high-end equipment (especially aseptic filling + automatic sealing system) is large, which puts heavy financial pressure on small and medium-sized enterprises. Second, the requirements for filling accuracy, sealing reliability, CIP (cleaning in place) functions, etc. have been improved, which puts higher standards on the R&D capabilities and integrated control of equipment manufacturers. Furthermore, consumers still have a low acceptance of some products (such as high-end wines and functional drinks), and have a "non-high-end" stereotype of BIB packaging. In addition, packaging bags (especially high-barrier multi-layer film bags) are mostly monopolized by a few global suppliers (such as Smurfit Kappa and DS Smith), which easily leads to price fluctuations and compatibility issues, which restricts the promotion of complete equipment.

Figure00001. Global Bag-in-box Packing Machine Market Size (US$ million), 2020-2031

Source: QYResearch, "Bag-in-box Packaging Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

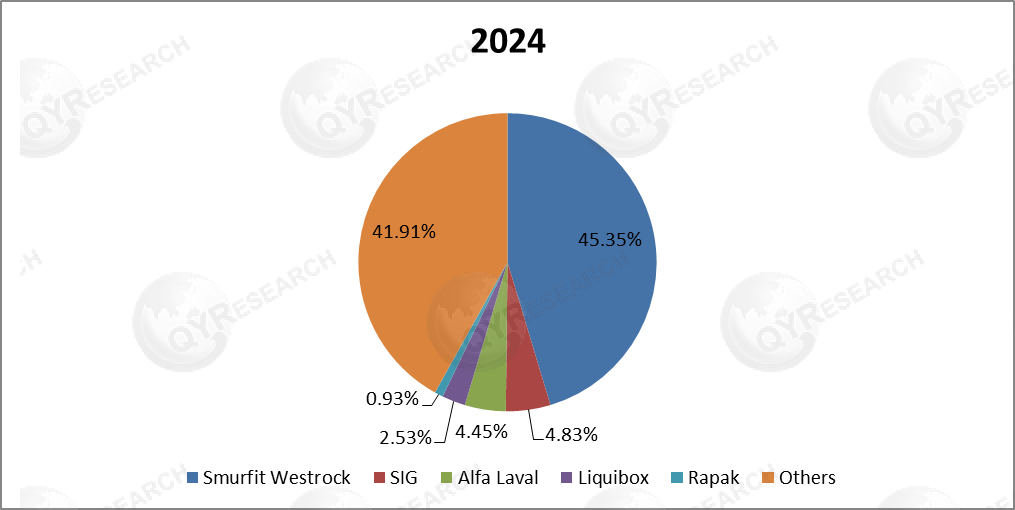

Figure00002. Global Bag-in-box Packing Machine Top 5 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Bag-in-box Packaging Machine - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Bag-in-box Packing Machine include Smurfit Westrock, SIG, Alfa Laval, Liquibox, Rapak, Rossi Ingegneria Alimentare Srl, Technibag, FBR ELPO, Shibo Fluid Technology, TECHNOLOGIA JSC, etc. In 2024, the global top 10 players had a share approximately 60.0% in terms of revenue.

The competitive landscape of the Bag-in-Box Packaging Machine market presents the characteristics of technology-driven + regional clustering + diversified applications. It is mainly dominated by high-end equipment manufacturers in Europe and the United States. China's production capacity is expanding rapidly and it is constantly entering the global low-end and customized markets. The following is a summary of the competition in this field and a description of the distribution of participants:

1. Market concentration is medium to high.

Although there are many small and medium-sized manufacturers, companies with core technologies and system integration capabilities in the global market are relatively concentrated, especially in high-end technology fields such as aseptic filling, weighing filling, and continuous packaging.

Chinese manufacturers have entered the market with the advantages of low-end and cost-effectiveness, which occupy an important position in the sub-segments such as tomato sauce, juice, dairy products, and chemical liquids, and gradually launched fully automated and modular solutions with export capabilities.

2. China's production capacity is rising rapidly and heading towards the international market.

3. The core of competition is concentrated on "automation degree + compatibility + filling accuracy".

The main competition points between enterprises are concentrated on the equipment:

Automation integration capability (sealing + weighing + labeling integration)

●Filling head adaptability (switching efficiency of different capacity bags/nozzle specifications)

●Footprint, cleaning convenience, production line compatibility

●After-sales service and equipment maintenance response speed (especially export market)

4. Downstream industry differentiation promotes customization capability competition.

BIB packaging is widely used in many industries (such as wine, dairy products, lubricants, biological reagents), and different liquid viscosities and hygiene requirements are different, which drives manufacturers to segment in the direction of "vertical special machines", and customization capabilities have become one of the competitive barriers.

In short, international giants maintain their high-end market share through technology, brands and systematic solutions, while Chinese manufacturers rely on cost-effectiveness and response speed to occupy a place in the mid-to-low-end and customized needs. Market competition is gradually transforming to a multi-dimensional "module integration capability + industry adaptation + customer service capability".

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.