Right Now

Bimetallic Composite Pipe Market Report: the global Bimetallic Composite Pipe market size is projected to reach USD 4.05 billion by 2031

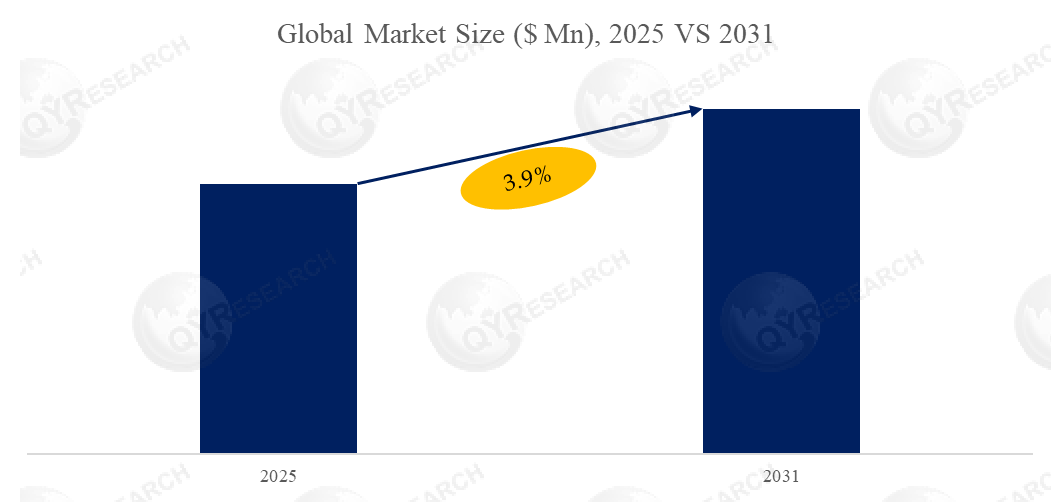

According to the new market research report “Bimetallic Composite Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Bimetallic Composite Pipe market size is projected to reach USD 4.05 billion by 2031, at a CAGR of 3.9% during the forecast period.

Figure00001. Global Bimetallic Composite Pipe Market Size (US$ Million), 2020-2031

Source: QYResearch, "Bimetallic Composite Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

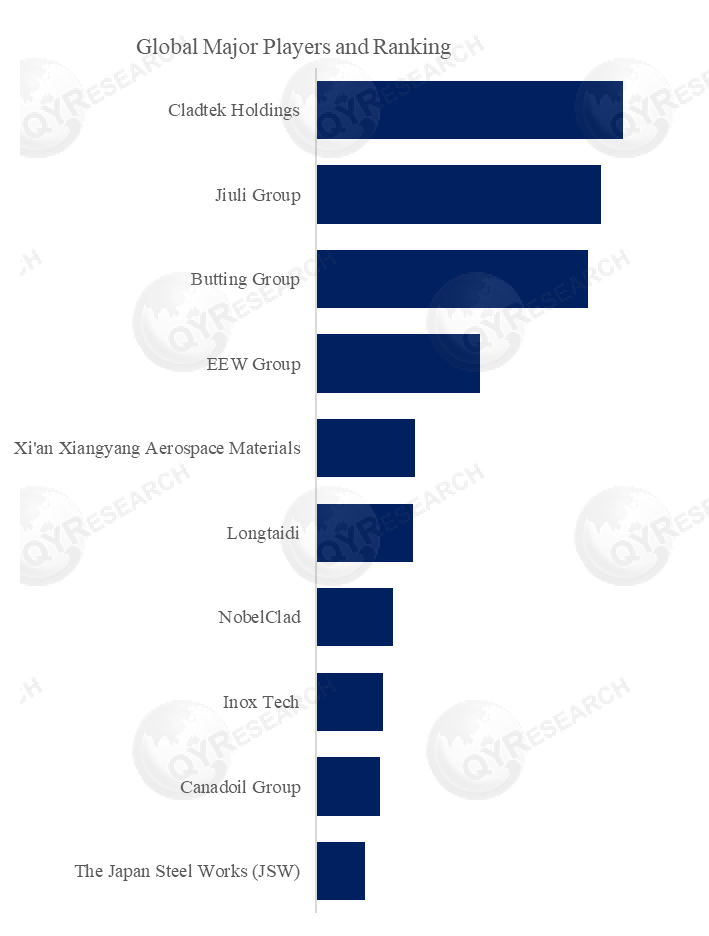

Figure00002. Global Bimetallic Composite Pipe Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Bimetallic Composite Pipe - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Bimetallic Composite Pipe include Cladtek Holdings, Jiuli Group, Butting Group, EEW Group, Xi'an Xiangyang Aerospace Materials, Longtaidi, NobelClad, Inox Tech, Canadoil Group, The Japan Steel Works (JSW), etc. In 2024, the global top 10 players had a share approximately 54.0% in terms of revenue.

In terms of product type, currently Roll Bonding Process is the largest segment, hold a share of 28.4%.

In terms of product application, currently Oil & Gas is the largest segment, hold a share of 69.9%.

Market Drivers:

Industries such as petrochemicals, natural gas, marine engineering, water treatment, nuclear power and hydrogen energy operate under high temperature, high pressure and strong corrosion environments, which put forward higher requirements on the corrosion resistance, safety and service life of pipeline systems. Bimetallic composite pipes have become an ideal material to replace stainless steel, titanium pipes and nickel alloy pipes because of their dual functions of corrosion-resistant inner layer and pressure-bearing outer layer, driving the continuous expansion of the market scale.

Single alloy pipes (such as titanium alloys and nickel-based alloys) are expensive, which restricts large-scale use. Bimetallic composite pipes use high-cost alloys only on the medium contact surface through structural optimization, and ordinary steel is used in other parts, which greatly reduces costs while maintaining the required performance. It meets the general pursuit of "cost-effective materials" in engineering projects and becomes an effective way to save materials and reduce costs in industry.

Restraint:

The manufacturing of high-quality bimetallic composite pipes has extremely high technical requirements for composite interface control, forming accuracy, non-destructive testing, etc. At present, the core processes such as explosive composite, hot-rolled composite, and hydraulic composite still need to be improved in terms of equipment intelligence, automation, and stability. Once the technical control is not in place, it is easy to cause product defects, interface peeling or failure, which will restrict product reliability and high-end market competitiveness.

At present, there are few unified standards for bimetallic composite pipes worldwide, and the testing standards and compliance requirements adopted by different countries and industries vary greatly, which can easily cause technical certification difficulties, customer understanding deviations, and even application accidents.

Bimetallic composite pipes are mostly used in major infrastructure and industrial projects. Their demand is greatly affected by international oil prices, energy investment, and chemical construction cycles, and has obvious cyclical and project-driven properties. Once the investment in downstream industries slows down or construction delays occur, it may lead to operating pressures such as reduced orders and overcapacity.

Opportunity:

In the future, more fusion composite processes will appear, such as hot rolling + hydraulic composite, explosion + heat treatment and other combined methods to improve interface bonding strength and dimensional consistency. At the same time, new processes such as centrifugal casting, powder metallurgy, and additive manufacturing will broaden the adaptability of composite metals to materials, structures, and shapes, and promote the development of special-shaped pipes, multi-layer composite pipes, and gradient functional materials.

In addition to the traditional combination of stainless steel and carbon steel, corrosion-resistant alloy materials such as titanium alloy, Hastelloy, zirconium alloy, duplex stainless steel, and aluminum alloy will be more used in the lining layer to cope with increasingly complex working conditions. At the same time, in the future, composite pipes may integrate multifunctional properties such as wear resistance, high temperature resistance, impact resistance, and electrochemical protection, and evolve towards "functional integrated composite materials".

In order to ensure the quality consistency and safety of composite pipes, the improvement and unification of standard systems (such as GB, ASTM, API) has become a trend. At the same time, composite pipe manufacturing is developing in the direction of intelligent control, online monitoring, digital evaluation of interface quality, etc., and cooperates with the full life cycle management system (LCA, digital twin, etc.) to improve the reliability and application efficiency in large-scale engineering projects.

In the future, the application of bimetallic composite pipes will gradually penetrate into emerging fields such as hydrogen energy transportation, carbon dioxide capture and storage (CCUS), high-temperature molten salt energy storage, semiconductor ultrapure water systems, deep-sea mining, polar engineering, etc. These scenarios put forward higher requirements for materials in terms of corrosion resistance, pressure resistance, lightweight and environmental protection, further promoting the upgrading of composite materials technology and the extension of application boundaries.

About The Authors

Lu Jing - Lead Author |

Email: lujing@qyresearch.com |

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 10 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.