Right Now

Hard carbon is a solid form of carbon that cannot be converted to graphite by heat-treatment, even at temperatures as high as 3000°C. It is also known as char, or non-graphitizing carbon. More colloquially it can be described as charcoal. Hard carbon is produced by heating carbonaceous precursors to approximately 1000°C in the absence of oxygen. Among the precursors for hard carbon are polyvinylidene chloride (PVDC), lignin and sucrose. Other precursors, such as polyvinyl chloride (PVC) and petroleum coke, produce soft carbon, or graphitizing carbon. Soft carbon can be readily converted to graphite by heating to 3000°C.

Hard carbon is currently the mainstream anode material route for sodium batteries. The commonly used hard carbon precursors are mainly bio-based, such as moso bamboo, coconut shell, starch, walnut shell, etc. At the same time, chemical raw materials such as anthracite, pitch, and phenolic resin can also be used. Synthetic polymer precursors such as phenolic resins are also included.

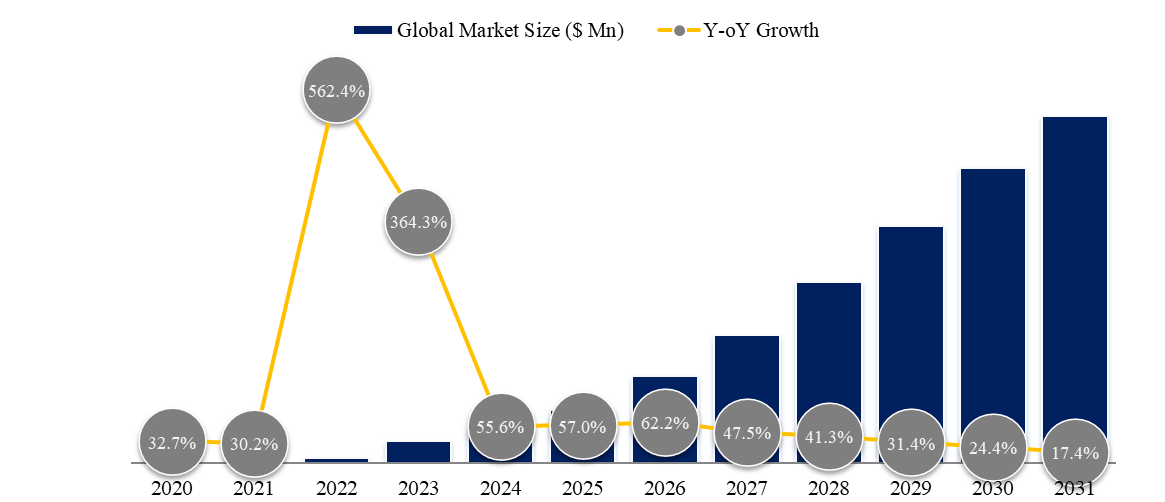

According to the new market research report “Sodium Ion Battery Hard Carbon - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Sodium Ion Battery Hard Carbon market size is projected to reach USD 0.61 billion by 2030, at a CAGR of 31.9% during the forecast period.

Figure 1. Global Sodium Ion Battery Hard Carbon Market Size (US$ Million), 2020-2031

Source: QYResearch, "Sodium Ion Battery Hard Carbon - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

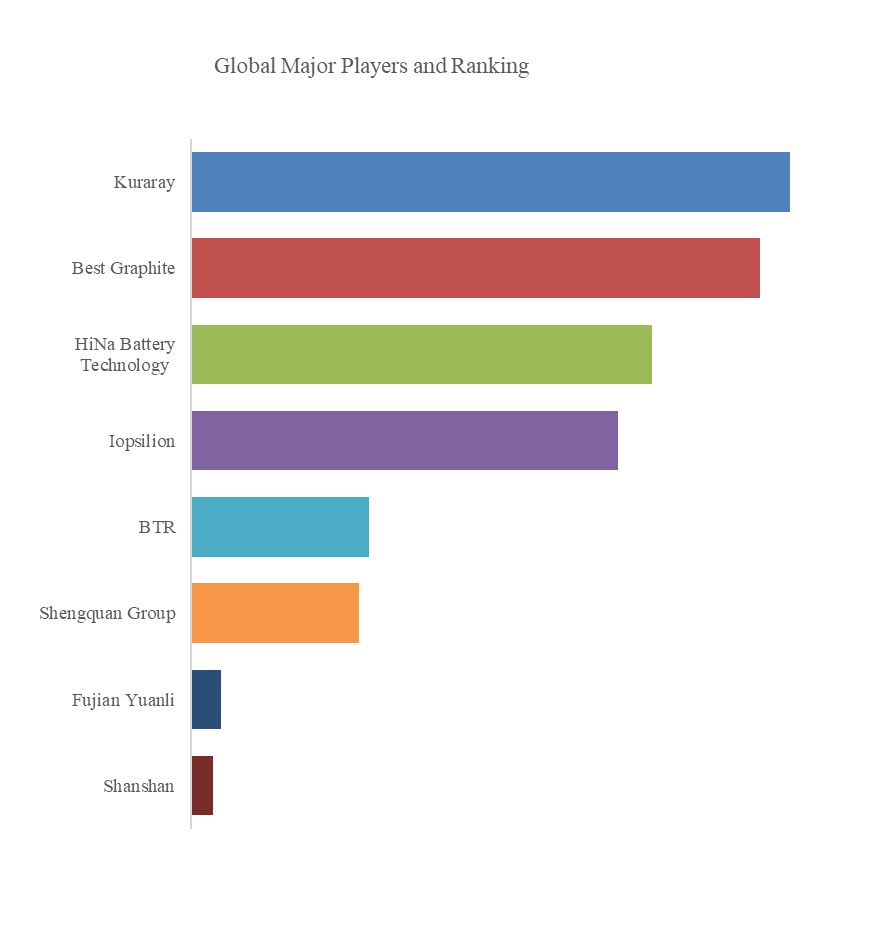

Figure 2. Global Sodium Ion Battery Hard Carbon Top 8 Players Ranking and Market Share

Source: QYResearch, "Sodium Ion Battery Hard Carbon - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Sodium Ion Battery Hard Carbon include Kuraray, Best Carbon, HiNa Battery Technology, Iopsilion, etc. In 2024, the global top four players had a share approximately 77.0% in terms of revenue.

In terms of product application, currently Energy Storage is the largest segment, hold a share of 91.5%.

In terms of product type, currently Bio-based is the largest segment, hold a share of 75.8%.

3.1 Market Trends

1.The Chinese market is back in action

In 2022, due to the high price of lithium carbonate in the upstream of the lithium battery industry, the sodium battery market is very hot. Many companies have laid out and increased their investment in the sodium battery market. As the price of lithium carbonate has fallen rapidly, the market's enthusiasm for sodium batteries has dropped, and many of the announced expansion plans have begun to be postponed and cancelled. By 2025, the price of lithium carbonate has fallen by more than 80% from its peak. The market expects that starting in 2025, the price of lithium carbonate will re-enter the upward channel, so the sodium battery market has become active again.

2.Technological Advancements in Hard Carbon

Hard carbon materials can store sodium in various locations and forms, with a theoretical capacity of up to 350-400 mAh/g. In addition, hard carbon materials enable the negative electrode to better achieve fast charging, solve the safety problem of over-discharge, and open up the breadth of sodium-ion battery applications.

3.There are various hard carbon precursor routes, supply and cost are core considerations

The biomass precursor process is less difficult, and biomass hard carbons such as coconut shells are industrialized quickly due to their excellent performance. However, when the industry enters a stage of growth and volume, it will be difficult to ensure the stability, low cost and consistency of the raw material supply chain, which will become a constraint. The current production process of hard carbons such as pitch-based/resin-based carbons is difficult and their performance is poor. However, their raw materials are widely supplied and low-cost. With technological breakthroughs in precursor research and development and the application of other material modification technologies, biomass polysaccharides and resin-based, asphalt-based and anthracite coal and other materials are expected to catch up from behind. Depending on the different demand and pain points in the application field, the future hard carbon route may show a flourishing pattern.

3.2 Market Drivers

1. There are various hard carbon precursor routes, supply and cost are core considerations

The biomass precursor process is less difficult, and biomass hard carbons such as coconut shells are industrialized quickly due to their excellent performance. However, when the industry enters a stage of growth and volume, it will be difficult to ensure the stability, low cost and consistency of the raw material supply chain, which will become a constraint. The current production process of hard carbons such as pitch-based/resin-based carbons is difficult and their performance is poor. However, their raw materials are widely supplied and low-cost. With technological breakthroughs in precursor research and development and the application of other material modification technologies, biomass polysaccharides and resin-based , asphalt-based and anthracite coal and other materials are expected to catch up from behind. Depending on the different demand and pain points in the application field, the future hard carbon route may show a flourishing pattern.

2. Growing demand for energy storage solutions

Grid Storage & Renewables Integration: Sodium-ion batteries are ideal for large-scale energy storage due to their safety, longevity, and cost benefits.

Low-Speed EVs & Backup Power: Emerging applications in e-bikes, scooters, and telecom backup systems are adopting SIBs for their thermal stability and affordability.

3.Government policies & incentives

China’s Dominance: The 14th Five-Year Plan prioritizes SIB development, with companies like CATL and HiNa Battery leading commercialization.

EU & U.S. Support: Funding for alternative battery tech (e.g., EU’s Horizon Europe, U.S. DOE grants) accelerates SIB adoption.

India’s Push for Localization: India is investing in sodium-ion R&D to reduce reliance on imported lithium.

3.3 Market Restraints

1. Immature supply chain & production scaling issues

Limited Hard Carbon Suppliers: Only a few companies produce high-quality hard carbon at scale.

Inconsistent Material Quality: Variations in biomass sources and pyrolysis methods lead to performance inconsistencies.

High Initial Capital Costs: Building dedicated SIB production lines requires investment, despite some compatibility with LIB manufacturing.

2. The current hard carbon price has limited room for decline

With the advancement of commercialization and the intensification of competition in recent years, the hard carbon price has dropped significantly, and there is not much room for decline in the next few years.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.