Right Now

Filament Winding Cylinders Industry Research:the market size is projected to reach USD 2.35 billion by 2031

Filament winding cylinders are advanced composite pressure vessels designed to store gases at high pressures, typically used for applications such as compressed natural gas (CNG), hydrogen storage, and breathing apparatus. They are manufactured using a filament winding process, where continuous fibers—often carbon, glass, or aramid—are wound around a cylindrical liner and then cured with resin to form a lightweight, high-strength structure. These cylinders offer excellent strength-to-weight ratios, corrosion resistance, and durability, making them ideal for use in automotive, aerospace, firefighting, and industrial gas sectors.

Market Drivers:

Lightweight and High-Strength Demand Across Industries: Filament-wound composite cylinders offer excellent strength-to-weight ratios, making them ideal for aerospace, automotive, defence, and pressure vessel applications where weight reduction is critical.

Growth in CNG, Hydrogen, and Industrial Gas Storage: Rising adoption of compressed natural gas (CNG) and hydrogen fuel in transportation and energy sectors is driving demand for Type III and Type IV composite cylinders made using filament winding.

Expansion of Clean Energy and Mobility Solutions: With global shifts toward low-emission vehicles and renewable energy systems, filament-wound cylinders are increasingly used for hydrogen-powered buses, fuel cell vehicles, and portable energy storage systems.

Superior Fatigue Resistance and Corrosion Protection: Compared to metal cylinders, filament-wound cylinders provide better corrosion resistance and fatigue life, reducing maintenance and extending service lifespan in harsh environments.

Advancements in Material Science and Automation: Innovations in carbon fiber, aramid, and epoxy resin systems, along with the use of automated winding machines and robotics, are improving production speed, consistency, and performance of wound cylinders.

Market Challenges

High Production Costs and Capital Investment: Filament winding equipment, raw materials (like carbon fibre), and skilled labor significantly increase initial costs, limiting adoption in cost-sensitive applications.

Material Supply and Price Volatility: The availability and cost of high-performance fibers such as carbon and aramid are subject to global supply chain fluctuations, impacting overall profitability and planning.

Complex Manufacturing Process: Filament winding requires precise control of tension, fiber placement, and curing, making quality control and repeatability challenging without advanced automation.

Limited Standardization and Certification: Safety-critical applications (e.g., hydrogen storage) require extensive testing, validation, and compliance with regional and international standards, which can delay product deployment.

Competition from Alternative Cylinder Technologies: In some applications, metal or hybrid cylinders may offer lower costs or simpler production, posing competition especially in markets where the performance-to-cost ratio is a primary concern.

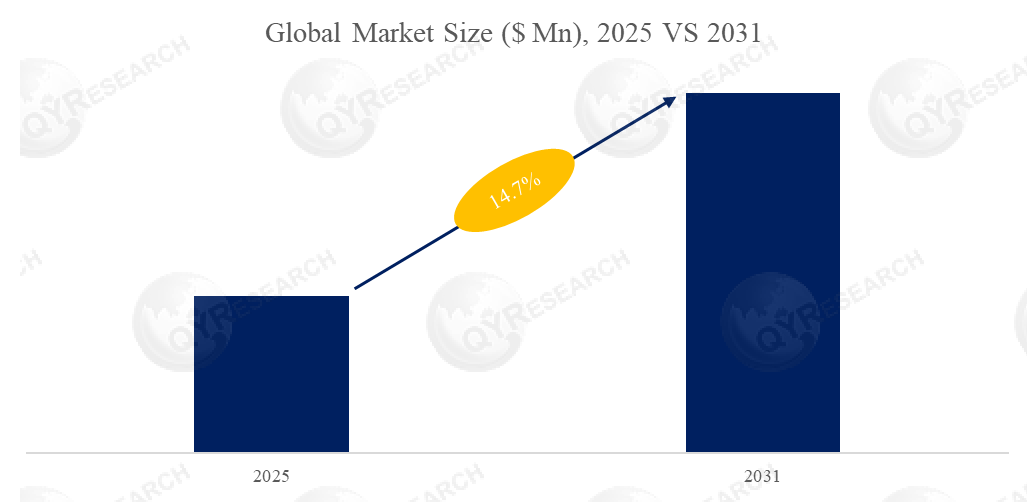

According to the new market research report “Filament Winding Cylinders - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”, published by QYResearch, the global Filament Winding Cylinders market size is projected to reach USD 2.35 billion by 2031, at a CAGR of 14.7% during the forecast period.

Figure00001. Global Filament Winding Cylinders Market Size (US$ Million), 2020-2031

Source: QYResearch, "Filament Winding Cylinders - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

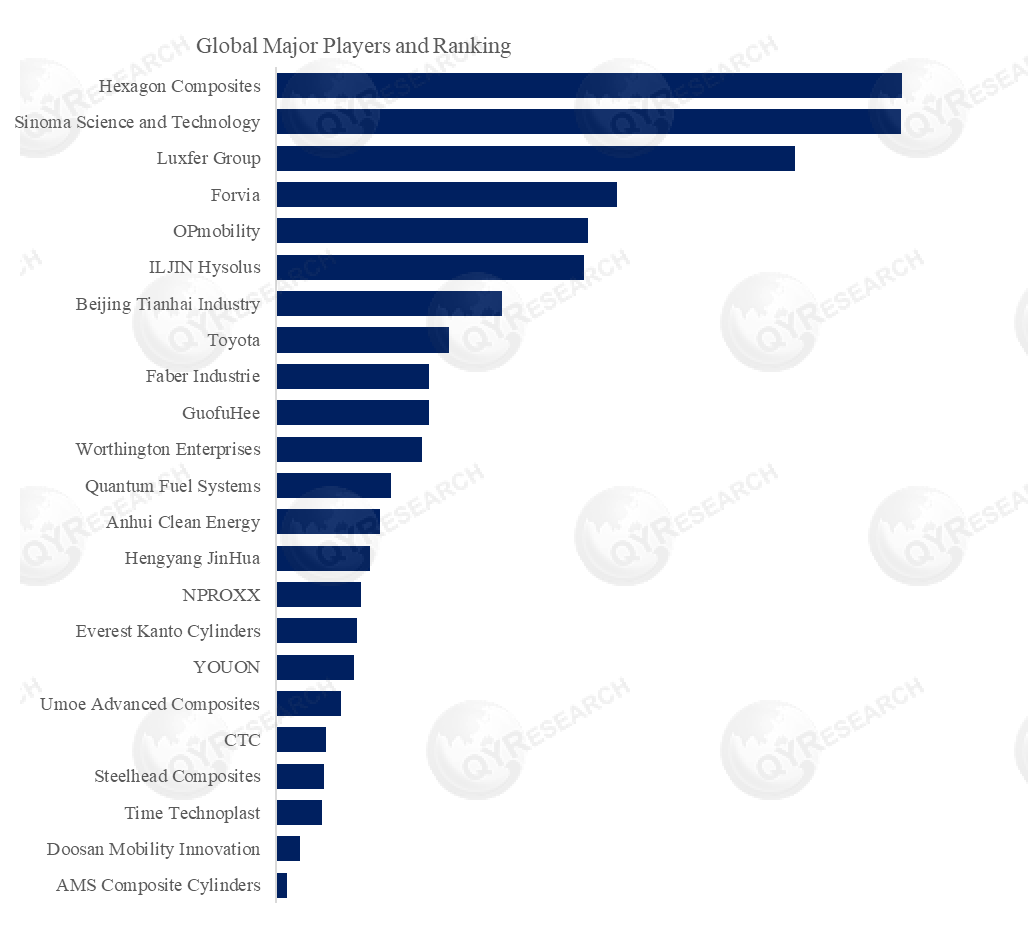

Figure00002. Global Filament Winding Cylinders Top 23 Players Ranking and Market Share (Ranking is based on the revenue of 2024, continually updated)

Source: QYResearch, "Filament Winding Cylinders - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031”

According to QYResearch Top Players Research Center, the global key manufacturers of Filament Winding Cylinders include Hexagon Composites, Sinoma Science and Technology, Luxfer Group, Forvia, OPmobility, ILJIN Hysolus, Beijing Tianhai Industry, Toyota, Faber Industrie, GuofuHee, etc. In 2024, the global top 10 players had a share approximately 63.0% in terms of revenue.

In terms of product type, currently Type IV is the largest segment, hold a share of 50.4%.

In terms of product application, currently Automotive and Transportation is the largest segment, hold a share of 39.7%.

About The Authors

Liu Wang- Lead Author |

Email: wangliu@qyresearch.com Tel: +86 15755356372 |

Ms. Wang has 7 years of industry research experience. She focuses on research related to the industry chain of automotive, consumer goods, software, and services, including auto parts, advanced automotive materials, various popular software, etc. Some research topics include Automotive Air Conditioning Electric Scroll Compressors, Lithium Battery Aluminum Plastic Film, Model-based Development (MBD), Predictive Maintenance Solutions, Webtoons, 3D models, Cloud Gaming Backend Service, Visual Content, DHA from Algae, etc. As an analyst with many years of experience in the consulting industry, she has a keen insight into the industry's market trends and developments and uses data analysis to discover potential market opportunities and threats, providing data support for corporate strategic decisions. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting (data is widely cited in prospectuses, annual reports and presentations), industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

More Posts

Report This Post

Please complete the following requested information to flag this post and report abuse, or offensive content. Your report will be reviewed within 24 hours. We will take appropriate action as described in Findit terms of use.